5. C modeling#

5.1. Characteristics of modeling#

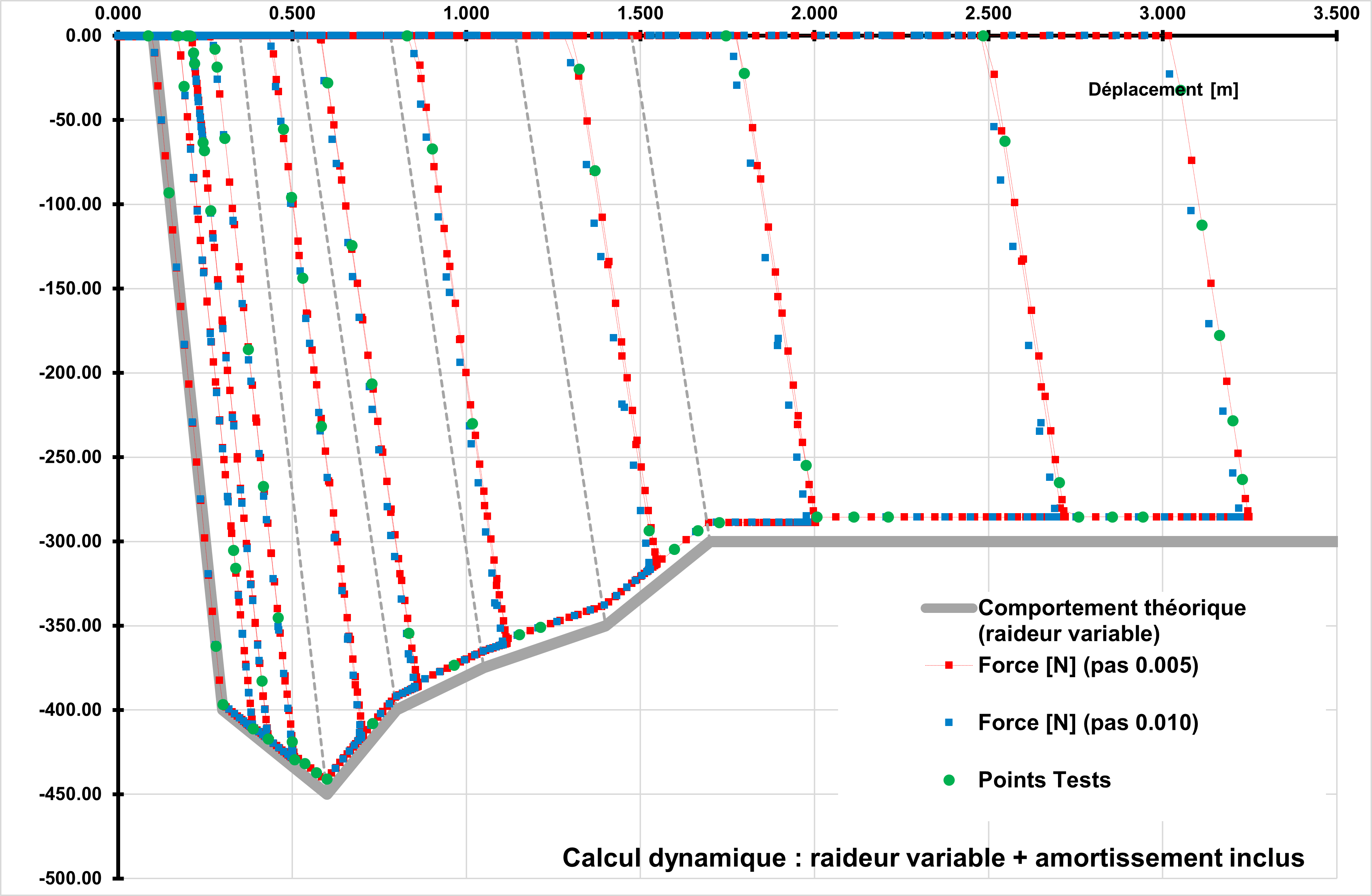

For the 1st calculation the time step is \(0.005\mathrm{s}\) (■). For the 2nd calculation the time step is \(0.010\mathrm{s}\) (■).

5.2. Tested sizes and results#

The quantities tested are the displacement coming from the load, the force existing in the discrete as well as the cumulative plasticity variable.

The figure below shows the curves from the 2 simulations. On top of these results are superimposed the curves resulting from the material parameters. The dashed discharges (- - - -) correspond to the stiffness defined in the material parameters.

The points (●) correspond to the tests carried out in the command file.

The difference between the effort and the theoretical value comes from taking into account the damping which « reduces » the threshold. The depreciation effect is taken into account in calculating the threshold. In the definition of material DIS_CHOC_ENDO: CRIT_AMOR **= “INCLUS”.

This lag has no reason to remain constant during the calculation, it is worth \(\text{Amor\_Nor}(p).V\).