3. Modeling A: Method MAILLAGE#

3.1. Characteristics of modeling#

In this modeling, the crack is not meshed. We use the X- FEM method and a representation of the crack by level sets. The level sets are updated by the operator PROPA_FISS, method MAILLAGE.

3.2. Characteristics of the mesh#

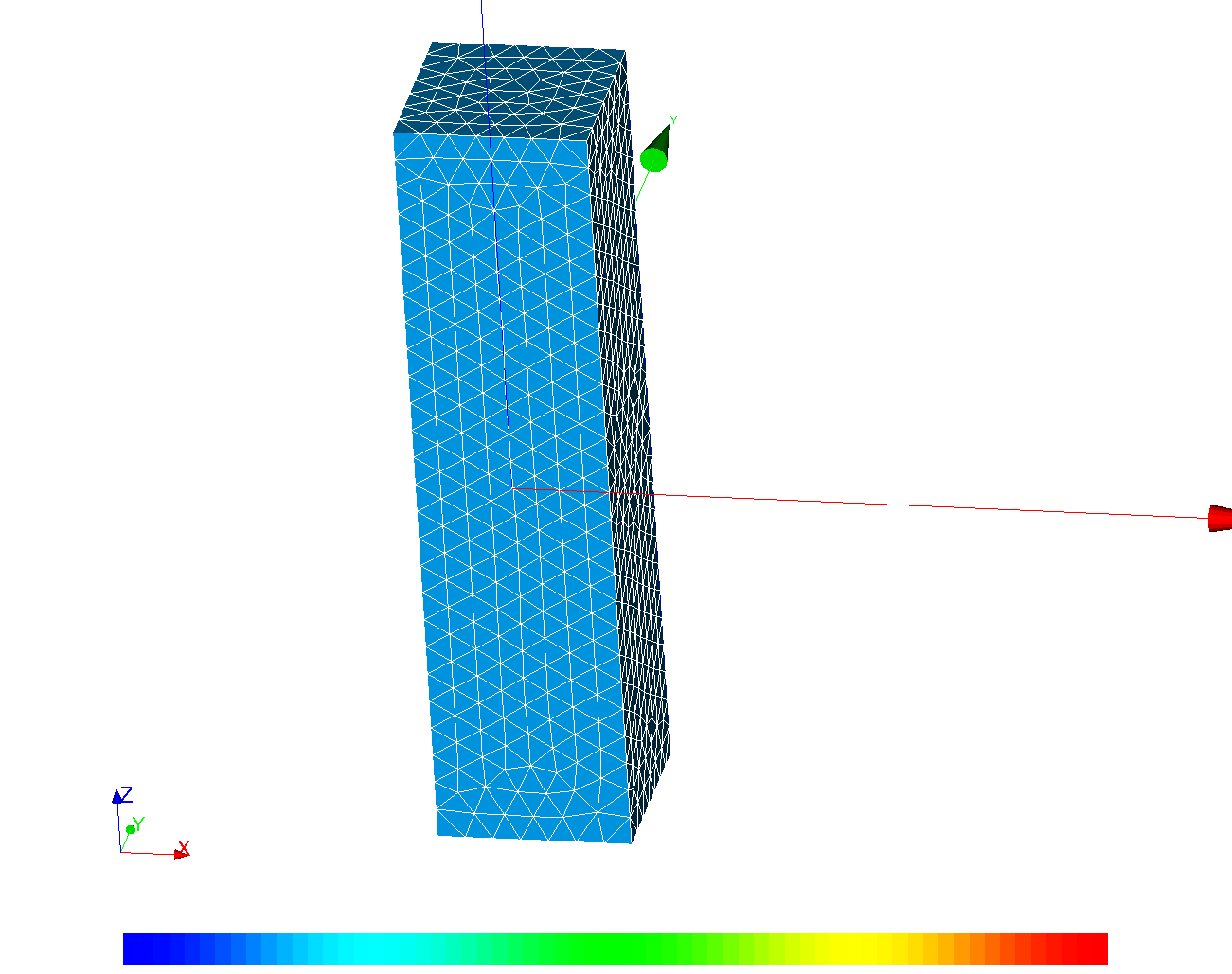

The initial mesh size of the structure is relatively coarse. It was made in Salomé’s module SMESH, with Blsurf and GHS3D. The size defined for the Blsurf surface mesh is \(2\mathit{mm}\).

mesh unit: meters

Number of knots: 2268

Number of meshes and type: 10690 TETRA4

Figure 3.2-1:

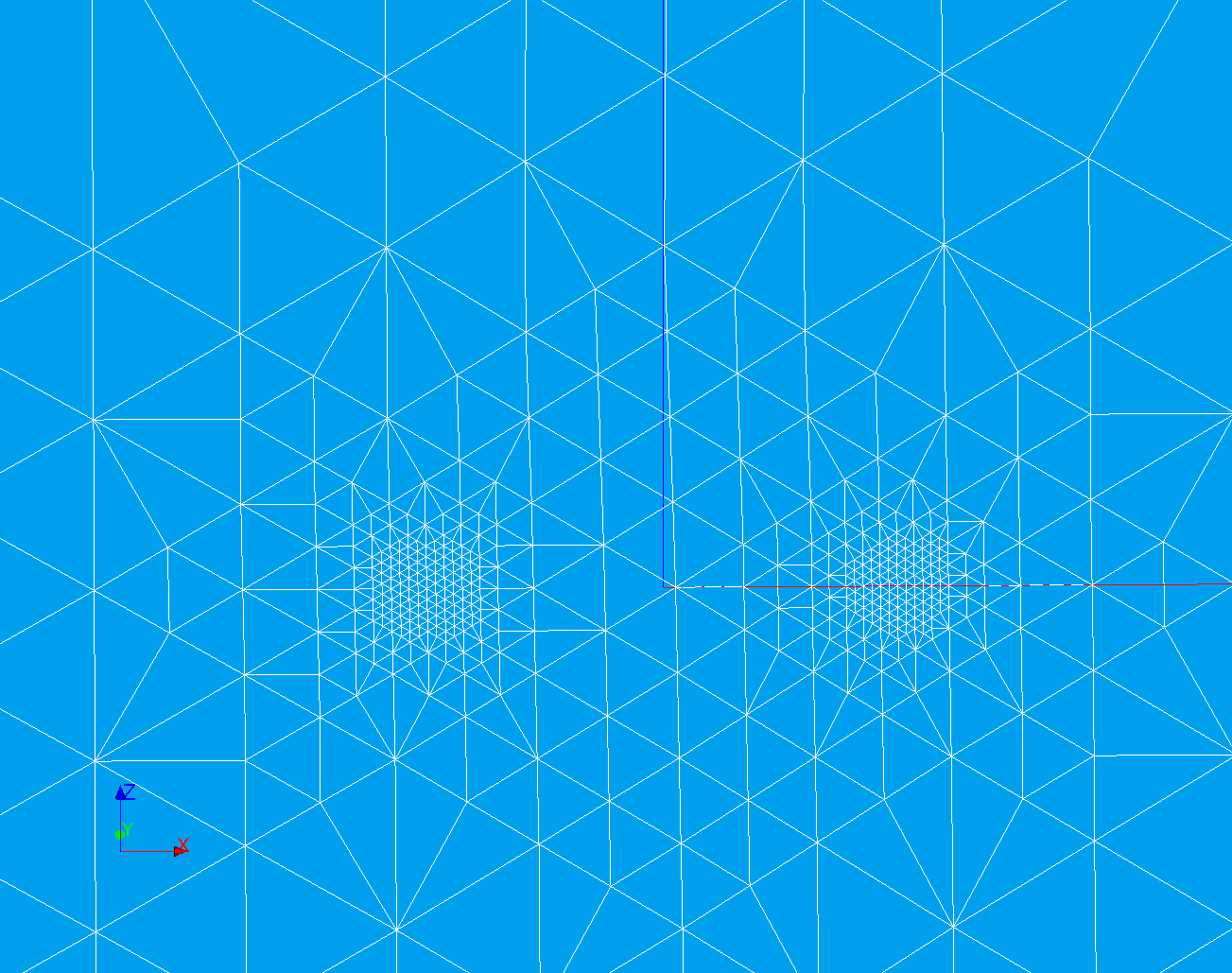

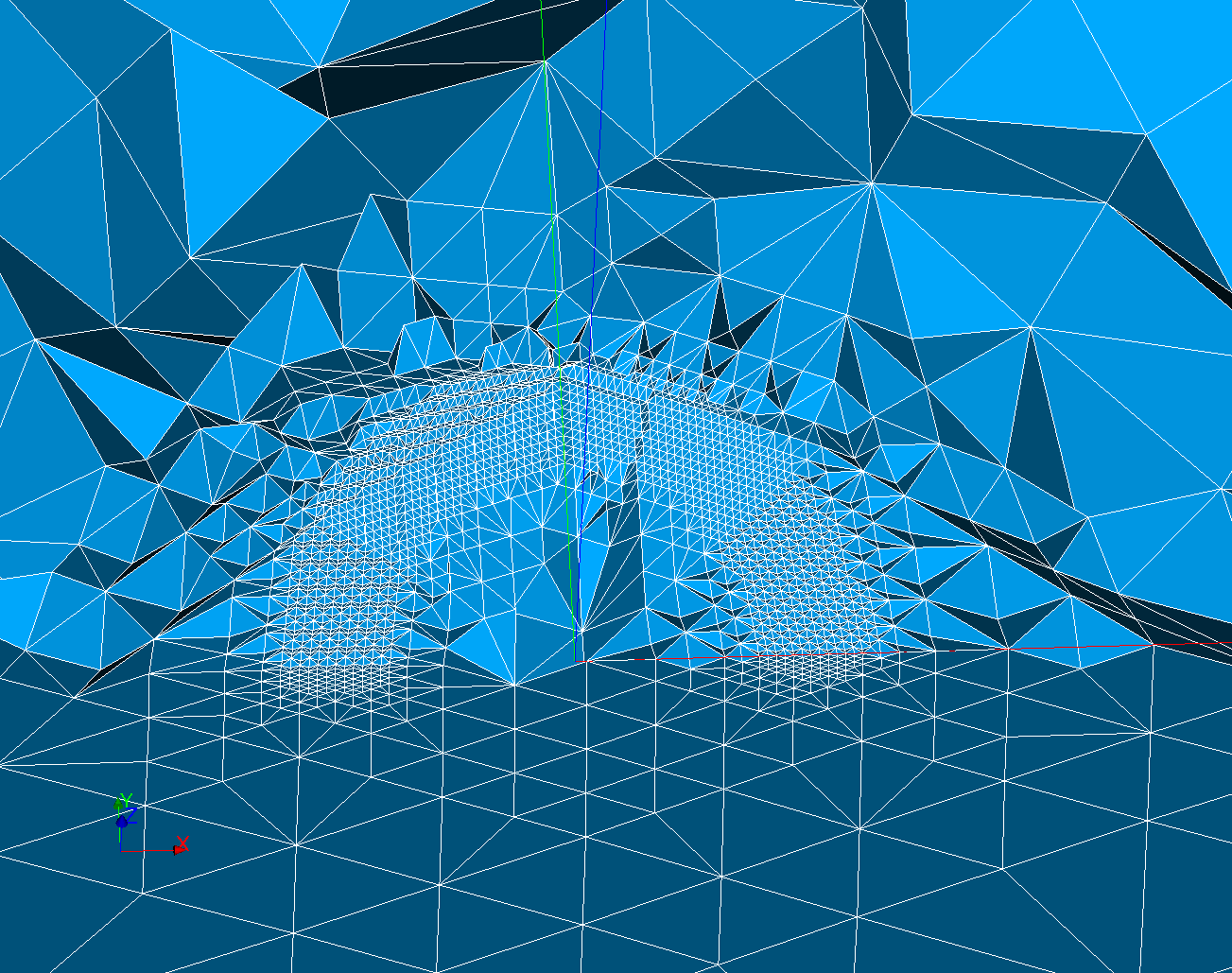

An automatic refinement procedure is put in place. After refinement around the crack bottom, the characteristic length of an element near the crack bottom is \(5\mu m\).

The refined mesh has the following characteristics:

Number of knots: 18325

Number of meshes and type: 103853 TETRA4

3.3. Boundary conditions and loads#

A traction force is applied to the upper and lower faces and the one on the right;

Rigid modes are blocked in the following way:

node \(A\): \(\mathit{DY}\mathrm{=}\mathit{DZ}\mathrm{=}0\), node \(B\): \(\mathit{DY}\mathrm{=}\mathit{DZ}\mathrm{=}0\), and node \(C\): \(\mathit{DX}\mathrm{=}\mathit{DZ}\mathrm{=}0\)

3.4. Tested sizes and results#

The position of the deepest crack bottom point is tested. This is equivalent to testing the maximum coordinate along the \(Y\) axis of the points at the bottom of the crack after a propagation step.

Identification |

Reference Type |

Reference Value |

% Tolerance |

\(\mathit{max}(Y)\) |

“SOURCE_EXTERNE” |

173.3 10-6 |

|