1. Reference problem#

1.1. Geometry#

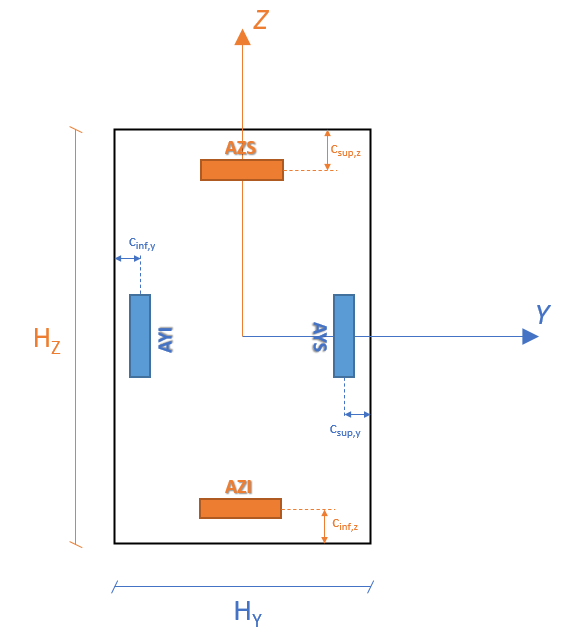

We consider a beam with a rectangular cross section, with dimensions \(h={H}_{Z}=\mathrm{0,3}m\) and \({b}_{w}={H}_{Y}=\mathrm{0,5}m\).

1.2. Material properties#

Not applicable to mechanical resolution (see § 1.3). See paragraph 1.3.2 for the parameters for determining the limit state for the material.

1.3. Boundary conditions and loads#

There is no mechanical resolution operator called in this test.

A generalized analytical field of effort is applied as input to the operator CALC_FERRAILLAGE, corresponding to one of the following configurations:

1.3.1. Case of loading at ELU#

compression force of \(1000000\text{N}\), and a shear force of \(100000\text{N}\) along the axis \(\text{Z}\)

traction force of \(1000000\text{N}\), and a shear force of \(-100000\text{N}\) along the axis \(\text{Z}\)

tensile force of \(1000000\text{N}\), a shear force of \(-100000\text{N}\) along the axis \(\text{Z}\) and a torsional moment of \(10000\text{Nm}\)

bending moment of \(100000\text{Nm}\) around the \(\text{Z}\) axis.

Bending moment of \(-100000\text{Nm}\) around the \(\text{Y}\) axis.

bending moment of \(-100000\text{Nm}\) around the \(\text{Z}\) axis and pull force of \(100000\text{N}\)

bending moment of \(-100000\text{Nm}\) around the \(\text{Y}\) axis and pull force of \(100000\text{N}\)

bending moment of \(-100000\text{Nm}\) around the \(\text{Z}\) axis and pull force of \(2000000\text{N}\)

bending moment of \(100000\text{Nm}\) around the \(\text{Z}\) axis and \(-150000\text{Nm}\) bending moment around the \(\text{Y}\) axis

bending moment of \(100000\text{Nm}\) around axis \(\text{Z}\), moment of bending of \(-150000\text{Nm}\) around axis \(\text{Y}\), and compression force of \(3000000\text{N}\)

bending moment of \(-150000\text{Nm}\) around the \(\text{Z}\) axis

bending moment of \(-260000\text{Nm}\) around the \(\text{Z}\) axis

bending moment of \(-380000\text{Nm}\) around the \(\text{Z}\) axis

compression force of \(4500000\text{N}\), bending moment of \(380000\text{Nm}\) around the axis \(\text{Z}\) and a shear force of \(100000\text{N}\) following \(\text{Z}\)

1.3.2. Load cases with the ELS Feature#

compression force of \(1000000\text{N}\), and a shear force of \(100000\text{N}\) along the axis \(\text{Z}\)

traction force of \(1000000\text{N}\), and a shear force of \(-100000\text{N}\) along the axis \(\text{Z}\)

tensile force of \(1000000\text{N}\), a shear force of \(-100000\text{N}\) along the axis \(\text{Z}\) and a torsional moment of \(10000\text{Nm}\)

bending moment of \(100000\text{Nm}\) around the \(\text{Z}\) axis.

Bending moment of \(-100000\text{Nm}\) around the \(\text{Y}\) axis.

bending moment of \(-100000\text{Nm}\) around the \(\text{Z}\) axis and pull force of \(100000\text{N}\)

bending moment of \(-100000\text{Nm}\) around the \(\text{Y}\) axis and pull force of \(100000\text{N}\)

bending moment of \(-100000\text{Nm}\) around the \(\text{Z}\) axis and pull force of \(2000000\text{N}\)

bending moment of \(100000\text{Nm}\) around the \(\text{Z}\) axis and \(-150000\text{Nm}\) bending moment around the \(\text{Y}\) axis

bending moment of \(100000\text{Nm}\) around axis \(\text{Z}\), moment of bending of \(-150000\text{Nm}\) around axis \(\text{Y}\), and compression force of \(3000000\text{N}\)

bending moment of \(-150000\text{Nm}\) around the \(\text{Z}\) axis

bending moment of \(-260000\text{Nm}\) around the \(\text{Z}\) axis

bending moment of \(-380000\text{Nm}\) around the \(\text{Z}\) axis

compression force of \(4500000\text{N}\), bending moment of \(380000\text{Nm}\) around the axis \(\text{Z}\) and a shear force of \(100000\text{N}\) following \(\text{Z}\)

1.3.3. Case of loading at the ELS Quasi-Permanent#

compression force of \(1000000\text{N}\), and a shear force of \(100000\text{N}\) along the axis \(\text{Z}\)

traction force of \(1000000\text{N}\), and a shear force of \(-100000\text{N}\) along the axis \(\text{Z}\)

tensile force of \(1000000\text{N}\), a shear force of \(-100000\text{N}\) along the axis \(\text{Z}\) and a torsional moment of \(10000\text{Nm}\)

bending moment of \(100000\text{Nm}\) around the \(\text{Z}\) axis.

Bending moment of \(-100000\text{Nm}\) around the \(\text{Y}\) axis.

bending moment of \(-100000\text{Nm}\) around the \(\text{Z}\) axis and pull force of \(100000\text{N}\)

bending moment of \(-100000\text{Nm}\) around the \(\text{Y}\) axis and pull force of \(100000\text{N}\)

bending moment of \(-100000\text{Nm}\) around the \(\text{Z}\) axis and pull force of \(2000000\text{N}\)

bending moment of \(100000\text{Nm}\) around the \(\text{Z}\) axis and \(-150000\text{Nm}\) bending moment around the \(\text{Y}\) axis

bending moment of \(100000\text{Nm}\) around axis \(\text{Z}\), moment of bending of \(-150000\text{Nm}\) around axis \(\text{Y}\), and compression force of \(3000000\text{N}\)

bending moment of \(-150000\text{Nm}\) around the \(\text{Z}\) axis

bending moment of \(-260000\text{Nm}\) around the \(\text{Z}\) axis

bending moment of \(-380000\text{Nm}\) around the \(\text{Z}\) axis

compression force of \(4500000\text{N}\), bending moment of \(380000\text{Nm}\) around the axis \(\text{Z}\) and a shear force of \(100000\text{N}\) following \(\text{Z}\)

1.4. Other calculation parameters#

1.4.1. Settings at ELU#

In ELU, we will consider 9 configurations on which we will start the calculation of the 14 load cases presented in §1.3.1:

Setup 1- Basic calculation:

calculation at EC2

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

elastic limit of steel fyk= 500 MPa

Young’s modulus of Eys steel = 210,000 MPa

type diagram (sant-901) for steel = “B2”

characteristic strength of concrete fck= 35 MPa

density of the steel [s] = 7800 Kg/m3

αcc= 1.0/γc= 1.5/γs= 1.15

Configuration 2- Taking into account compression reinforcement:

calculation at EC2

FERR_COMP = “OUI “

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

elastic limit of steel fyk= 500 MPa

Young’s modulus of Eys steel = 210,000 MPa

type diagram (sant-901) for steel = “B2”

characteristic strength of concrete fck= 35 MPa

density of the steel [s] = 7800 Kg/m3

αcc= 1.0/γc= 1.5/γs= 1.15

Configuration 3- Taking into account the impact of compression on the shear force resistance and the impact of shear force and torsion on the longitudinal reinforcement:

calculation at EC2

FERR_COMP = “OUI “

UTIL_COMPR = “OUI “

EPURE_CISA = “OUI “

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

elastic limit of steel fyk= 500 MPa

Young’s modulus of Eys steel = 210,000 MPa

type diagram (sant-901) for steel = “B2”

characteristic strength of concrete fck= 35 MPa

density of the steel [s] = 7800 Kg/m3

αcc= 1.0/γc= 1.5/γs= 1.15

Configuration 4- Search for a symmetric sizing reinforcement:

calculation at EC2

FERR_COMP = “OUI “

FERR_SYME = “OUI “

SEUIL_SYME = 1 cm2

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

elastic limit of steel fyk= 500 MPa

Young’s modulus of Eys steel = 210,000 MPa

type diagram (sant-901) for steel = “B2”

characteristic strength of concrete fck= 35 MPa

density of the steel [s] = 7800 Kg/m3

αcc= 1.0/γc= 1.5/γs= 1.15

Configuration 5- Sizing at BAEL91:

calculation at BAEL91

FERR_COMP = “OUI “

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

elastic limit of steel Fe= 500 MPa

Young’s modulus of Eys steel = 210,000 MPa

type diagram (sant-901) for steel = “B2”

characteristic strength of concrete fcj= 35 MPa

density of the steel [s] = 7800 Kg/m3

αcc= 1.0/γc= 1.5/γs= 1.15

1.4.2. Parameters with the ELS Feature#

In ELS Characteristic, we will consider 4 configurations on which we will start the calculation of the 10 load cases presented in §1.3.2:

Setup 1- Basic calculation:

calculation at EC2

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

characteristic strength of concrete fck= 35 MPa

authorized limit stress in steel: μs, lim = 400 MPa

maximum compressive stress authorized at the level of the underside of concrete:

►c, inf, lim = 21 MPa

maximum compressive stress authorized at the level of the underside of concrete:

►c, sup, lim=21 MPa

steel-concrete equivalence coefficient: αE = 15

density of the steel [s] = 7800 Kg/m3

Configuration 2- Taking into account compression reinforcement:

calculation at EC2

FERR_COMP = “OUI “

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

characteristic strength of concrete fck= 35 MPa

authorized limit stress in steel: μs, lim = 400 MPa

maximum compressive stress authorized at the level of the underside of concrete:

►c, inf, lim = 21 MPa

maximum compressive stress authorized at the level of the underside of concrete:

►c, sup, lim=21 MPa

steel-concrete equivalence coefficient: αE = 15

density of the steel [s] = 7800 Kg/m3

Configuration 3- Search for a symmetric sizing reinforcement:

calculation at EC2

FERR_COMP = “OUI “

FERR_SYME = “OUI “

SEUIL_SYME = 5 cm2

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

characteristic strength of concrete fck= 35 MPa

authorized limit stress in steel: μs, lim = 400 MPa

maximum compressive stress authorized at the level of the underside of concrete:

►c, inf, lim = 21 MPa

maximum compressive stress authorized at the level of the underside of concrete:

►c, sup, lim=21 MPa

steel-concrete equivalence coefficient: αE = 15

density of the steel [s] = 7800 Kg/m3

Setup 4- Calculation at BAEL91

calculation at BAEL91

FERR_COMP = “OUI “

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

characteristic strength of concrete FCj= 35 MPa

authorized limit stress in steel: μs, lim = 400 MPa

maximum compressive stress authorized at the level of the underside of concrete:

S-C, INF, LIM = 21 MPa

maximum compressive stress authorized at the level of the underside of concrete:

S-C, SUP, LIM = 21 MPa

steel-concrete equivalence coefficient: N = 15

density of the steel [s] = 7800 Kg/m3

1.4.3. Settings at the ELS Quasi-Permanent#

At ELS Permanent4 configurations will be considered on which we will start the calculation of the 10 load cases presented in §1.3.3:

Setup 1- Basic calculation:

calculation at EC2

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

characteristic strength of concrete fck= 35 MPa

elastic limit of steel: fyk = 500 MPa

Young’s modulus of steel: Eys = 210,000 MPa

maximum crack opening allowed on the underside: wmax, inf = 0.15 mm

maximum crack opening allowed on the upper side: wmax, sup = 0.15 mm

loading time coefficient: kt= 0.4

maximum compressive stress allowed in concrete for the control of non-linear creep: μc, lim, NL= 15.75 MPa

estimated diameter of the bars on the lower face along the X axis: Φ INF, X = 25 mm

estimated diameter of the bars on the upper face along the X axis: Φ SUP, X= 25 mm

estimated diameter of the bars on the lower face along the Y axis: Φ INF, Y= 25 mm

estimated diameter of the bars on the upper face along the Y axis: Φ SUP, Y= 25 mm

steel-concrete equivalence coefficient: αE = 15

density of the steel [s] = 7800 Kg/m3

Configuration 2- Taking into account compression reinforcement:

calculation at EC2

FERR_COMP = “OUI “

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

characteristic strength of concrete fck= 35 MPa

elastic limit of steel: fyk = 500 MPa

Young’s modulus of steel: Eys = 210,000 MPa

maximum crack opening allowed on the underside: wmax, inf = 0.15 mm

maximum crack opening allowed on the upper side: wmax, sup = 0.15 mm

loading time coefficient: kt= 0.4

maximum compressive stress allowed in concrete for the control of non-linear creep: μc, lim, NL= 15.75 MPa

estimated diameter of the bars on the lower face along the X axis: Φ INF, X = 25 mm

estimated diameter of the bars on the upper face along the X axis: Φ SUP, X= 25 mm

estimated diameter of the bars on the lower face along the Y axis: Φ INF, Y= 25 mm

estimated diameter of the bars on the upper face along the Y axis: Φ SUP, Y= 25 mm

steel-concrete equivalence coefficient: αE = 15

density of the steel [s] = 7800 Kg/m3

Configuration 3- Search for a symmetric sizing reinforcement:

calculation at EC2

FERR_COMP = “OUI “

FERR_SYME = “OUI “

SEUIL_SYME = 5 cm2

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

characteristic strength of concrete fck= 35 MPa

elastic limit of steel: fyk = 500 MPa

Young’s modulus of steel: Eys = 210,000 MPa

maximum crack opening allowed on the underside: wmax, inf = 0.15 mm

maximum crack opening allowed on the upper side: wmax, sup = 0.15 mm

loading time coefficient: kt= 0.4

maximum compressive stress allowed in concrete for the control of non-linear creep: μc, lim, NL= 15.75 MPa

estimated diameter of the bars on the lower face along the X axis: Φ INF, X = 25 mm

estimated diameter of the bars on the upper face along the X axis: Φ SUP, X= 25 mm

estimated diameter of the bars on the lower face along the Y axis: Φ INF, Y= 25 mm

estimated diameter of the bars on the upper face along the Y axis: Φ SUP, Y= 25 mm

steel-concrete equivalence coefficient: αE = 15

density of the steel [s] = 7800 Kg/m3

Setup 4- Calculation at BAEL91

calculation at BAEL91

FERR_COMP = “OUI “

upper csup coating, Y = csup, Z =4 cm

lower cinf coating, Y = cinf, Z = 4 cm

characteristic strength of concrete fck= 35 MPa

elastic limit of steel: fyk = 500 MPa

Young’s modulus of steel: Eys = 210,000 MPa

maximum crack opening allowed on the underside: wmax, inf = 0.15 mm

maximum crack opening allowed on the upper side: wmax, sup = 0.15 mm

loading time coefficient: kt= 0.4

maximum compressive stress allowed in concrete for the control of non-linear creep: μc, lim, NL= 15.75 MPa

estimated diameter of the bars on the lower face along the X axis: Φ INF, X = 25 mm

estimated diameter of the bars on the upper face along the X axis: Φ SUP, X= 25 mm

estimated diameter of the bars on the lower face along the Y axis: Φ INF, Y= 25 mm

estimated diameter of the bars on the upper face along the Y axis: Φ SUP, Y= 25 mm

steel-concrete equivalence coefficient: αE = 15

density of the steel [s] = 7800 Kg/m3