1. Reference problem#

1.1. Problem#

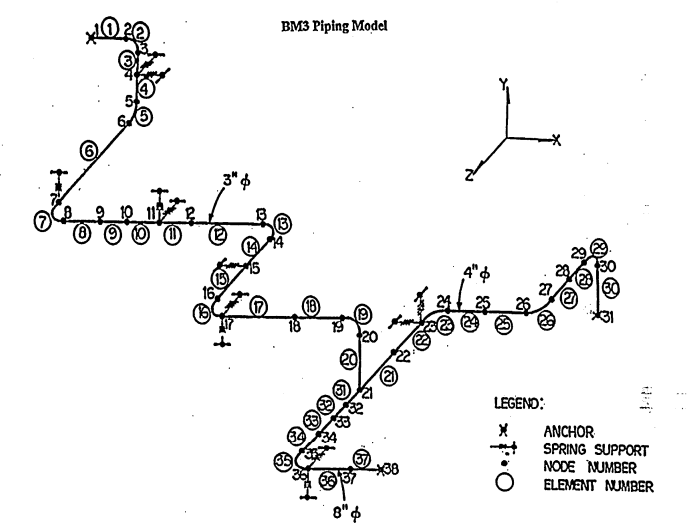

This test consists in carrying out a spectral analysis of the pipe network BM3 used in a nuclear power plant. It makes it possible to validate the various combination methods used, including the Gupta method. To carry out this validation, the results of an equivalent modeling conducted with ANSYS are extracted from the following two documents:

[1] Reevaluation of Regulatory Guidance on Modal Response Combination Methods for Seismic Response Spectrum Analysis, NUREG /CR-6645, BNL - NUREG -52576, 1999.

[2] ANSYS Mechanical APDL Technology Demonstration Guide, 2010, Chapter 12: Dynamic Simulation of a Nuclear Piping System Using RSA Methods.

1.2. Geometry#

The geometry is wireframe. The following figure, taken from document [1], shows this geometry:

In order to compare correctly with American studies [1] and [2], the units chosen are imperial units.

The structure is composed of three parts with different sections. The following table shows the characteristics of the sections:

Radius (inch) |

Thickness (inch) |

|

section 1 |

1.75 |

0.216 |

section 2 |

2.25 |

0.237 |

section 3 |

4.31 |

0.322 |

1.3. Meshing#

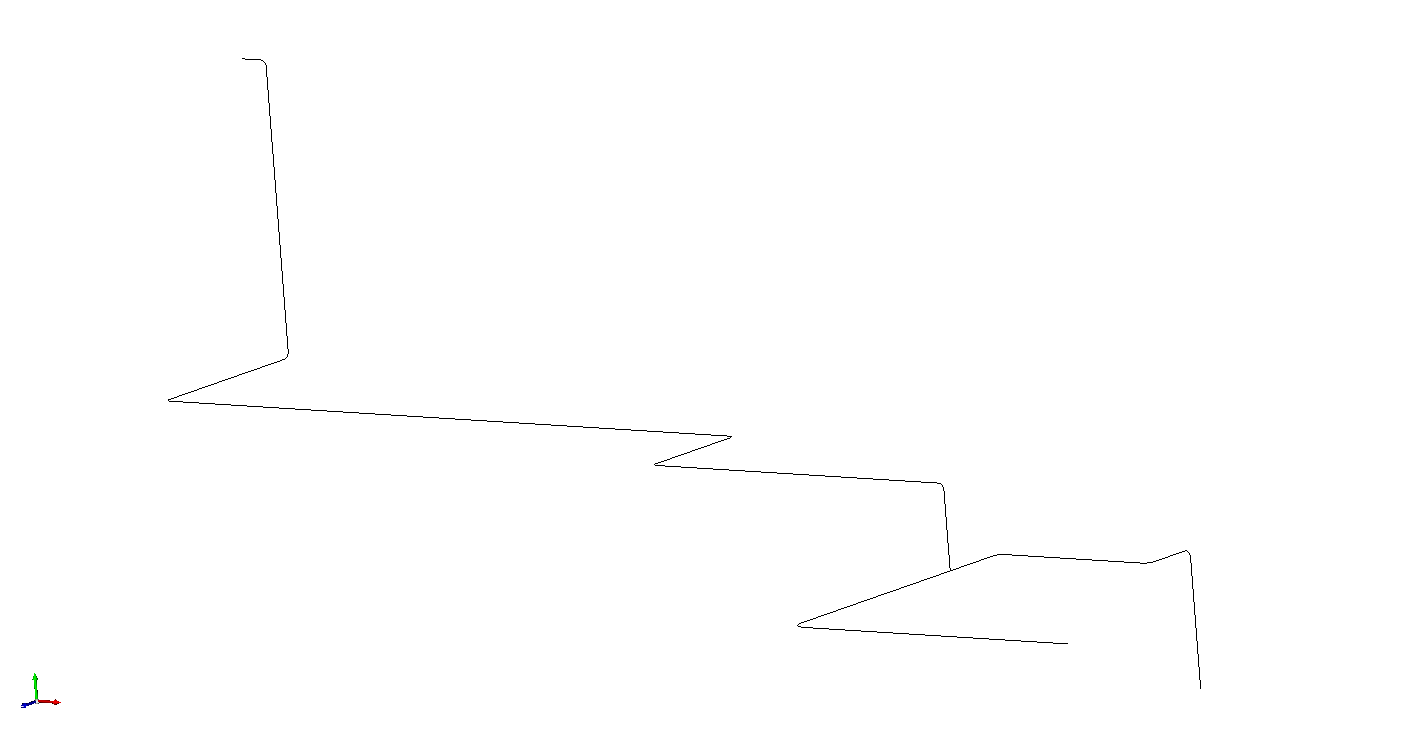

The structure’s mesh is linear and composed of 37 SEG2 elements for 38 nodes.

The following figure shows the mesh under SALOME - MECA -2012.1:

The following table shows the coordinates of the mesh nodes:

Coordinates (inch) |

|||

Knots |

\(X\) |

\(Y\) |

\(Z\) |

1 |

0 |

0 |

0 |

2 |

15 |

0 |

0 |

3 |

19.5 |

-4.5 |

0 |

4 |

19.5 |

-180 |

0 |

5 |

19.5 |

-199,5 |

0 |

6 |

19.5 |

-204 |

4.5 |

7 |

19.5 |

-204 |

139.5 |

8 |

24 |

-204 |

144 |

9 |

96 |

-204 |

144 |

10 |

254 |

-204 |

144 |

11 |

333 |

-204 |

144 |

12 |

411 |

-204 |

144 |

13 |

483 |

-204 |

144 |

14 |

487.5 |

-204 |

148.5 |

15 |

487.5 |

-204 |

192 |

16 |

487.5 |

-204 |

235.5 |

17 |

492 |

-204 |

240 |

18 |

575 |

-204 |

240 |

19 |

723 |

-204 |

240 |

20 |

727.5 |

-208.5 |

240 |

21 |

727.5 |

-264 |

240 |

22 |

727.5 |

-264 |

205 |

23 |

727.5 |

-264 |

190 |

24 |

733.5 |

-264 |

184 |

25 |

753.5 |

-264 |

184 |

26 |

845.5 |

-264 |

184 |

27 |

851.5 |

-264 |

178 |

28 |

851.5 |

-264 |

160 |

29 |

851.5 |

-264 |

142 |

30 |

851.5 |

-270 |

136 |

31 |

851.5 |

-360 |

136 |

32 |

727.5 |

-264 |

255 |

33 |

727.5 |

-264 |

270 |

34 |

727.5 |

-264 |

306 |

35 |

727.5 |

-264 |

414 |

36 |

739.5 |

-264 |

426 |

37 |

847.5 |

-264 |

426 |

38 |

955.5 |

-264 |

426 |

The supports of this structure are modelled by stiffness. To be able to recover the nodal reactions to the supports, an additional « duplicate » node is created for each support. It is offset by \(\mathrm{1,E-3}\mathit{inch}\) (Code_Aster tolerance) along the \(X\) axis with respect to the support point. All its degrees of freedom are blocked and a SEG2 element is created between the support node and the « duplicate ». It is on this element that the values of the stiffness of the supports will be applied. Thus, the nodal reactions will be recorded at the « duplicate » nodes.

1.4. Materials#

The material properties of the structure are as follows:

\(E\mathrm{=}\mathrm{2,9E+7}\mathit{pound}\mathrm{/}{\mathit{inch}}^{2}\)

\(\nu \mathrm{=}\mathrm{0,3}\)

The densities of the structure are as follows:

Radius (inch) |

Thickness (inch) |

Thickness (inch) |

Linear mass (pound/inch) |

Thickness (inch) |

Thickness (inch) |

|

section 1 |

1.7500 |

0.216 |

0.216 |

2.2273 |

2.3240E-003 |

1.0434E-003 |

section 2 |

2.2500 |

0.237 |

0.237 |

3.1724 |

3.5145E-003 |

1.1078E-003 |

section 3 |

4.3125 |

0.322 |

0.322 |

8.3950 |

1.0836E-002 |

1.2908E-003 |

Note: In document [2] from 2010, the density in section 3 is \(1.253E\mathrm{-}3\mathit{pound}\mathrm{/}{\mathit{inch}}^{3}\). In order to maintain consistency in all models, the value of the 1999 document [1] is used.

1.5. Boundary conditions and loads#

The boundary conditions correspond to the supports of the structure. They are modelled by stiffness at the corresponding nodes of the mesh. The stiffness is as follows:

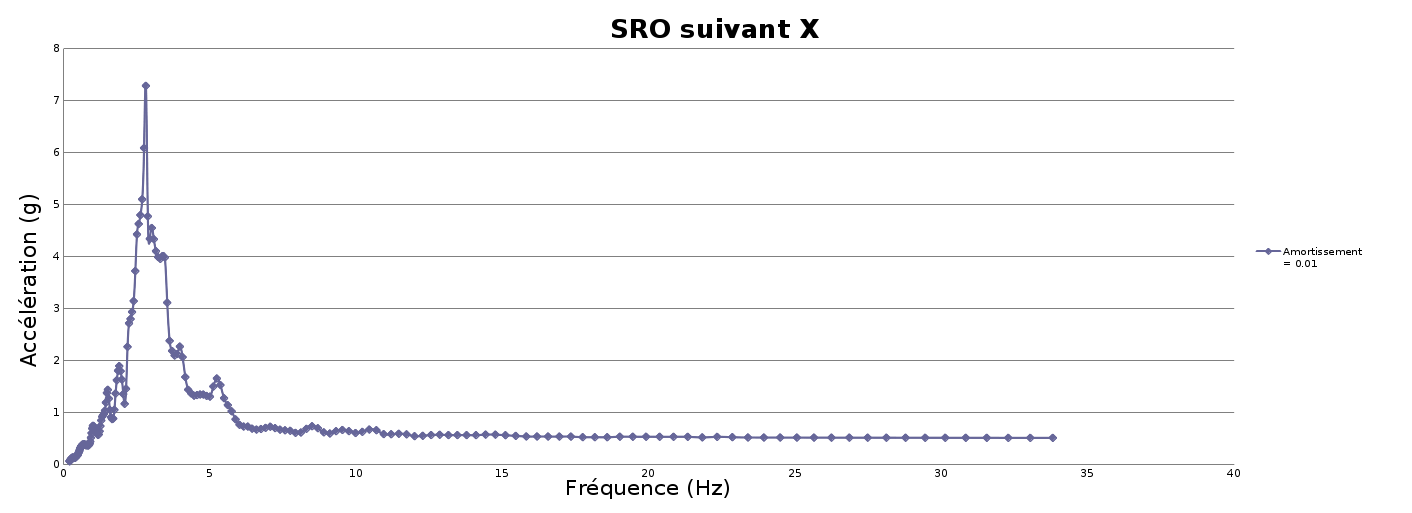

The loading of the spectral analysis corresponds to an Oscillator Response Spectrum applied in the \(X\) direction. The spectrum is shown in the following graph:

1.6. Modeling#

Element POUTRE (2 models):

modeling POU_D_T for straight sections and for curved sections

DIS_TR modeling for supports