1. Reference problem#

1.1. Geometry#

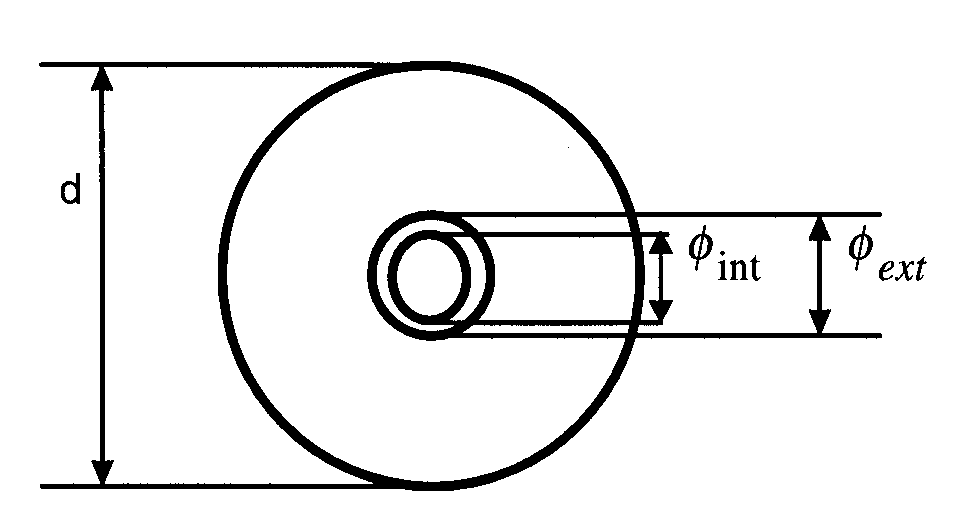

The tube in question is a hollow cylinder whose characteristic dimensions are as follows:

length |

\(L=1m\) |

outside diameter |

\({\phi }_{\text{ext}}=13\mathrm{mm}\) |

inner diameter |

\({\phi }_{\text{int}}=\mathrm{8,8}\mathrm{mm}\) |

The tube is placed in the center of a cylindrical chamber with a circular cross section. The inside diameter of the enclosure is \(d=5\mathrm{cm}\).

The roughness of the walls of the tube is \(\varepsilon ={10}^{–5}m\).

1.2. Material properties#

The physical characteristics of the material PVC constituting the tube are as follows:

Young’s module |

\(E=\mathrm{2,80}\mathrm{.}{10}^{9}\mathrm{Pa}\) |

Poisson’s ratio |

\(\nu =\mathrm{0,3}\) |

density |

\(\rho =1500\mathrm{kg}/{m}^{3}\) |

The water surrounding the tube has the following properties:

density |

\({\rho }_{\mathrm{eau}}=1000\mathrm{kg}/{m}^{3}\) |

kinematic viscosity |

\({\nu }_{\mathrm{eau}}=\mathrm{1,1}.10–6{m}^{2}/s\) |

1.3. Boundary conditions and loads#

The two ends of the tube are connected to fixed supports by two metal rods. The relative flexibility of these rods frees up the degrees of freedom of rotation of the ends of the tube. It can therefore be estimated that the conditions for supporting the tube are of the ball-and-swivel type, the metal rods introducing an additional rotational stiffness at each end.

In addition, these rods make it possible to apply an axial force to the tube, which can thus be prestressed in tension or in compression. In practice, two configurations are studied:

pipe not prestressed: no force is applied. This configuration corresponds to the modeling A of the test case,

tube prestressed in compression by applying an axial force of \(40N\) at one end.

This configuration corresponds to model B of the test case.

1.4. Bibliographical reference#

TANAKA, K. FUJITA, A. HOTTA and N. KONO: « Parallel flow-induced damping of PWR fuel assembly », ASME Conference, Pittsburgh, PA, PVP Vol. 133 (1988)