1. Reference problem#

1.1. Geometry#

The pipe is modelled by a hollow circular section 762mm in diameter and 22mm thick (S1) or 813mm in diameter and 23mm thick (S2). The modeling is done with SEG2 (element POU_D_T) only.

Symbol |

Description |

|

Point mass |

|

0D spring in translation and/or rotation |

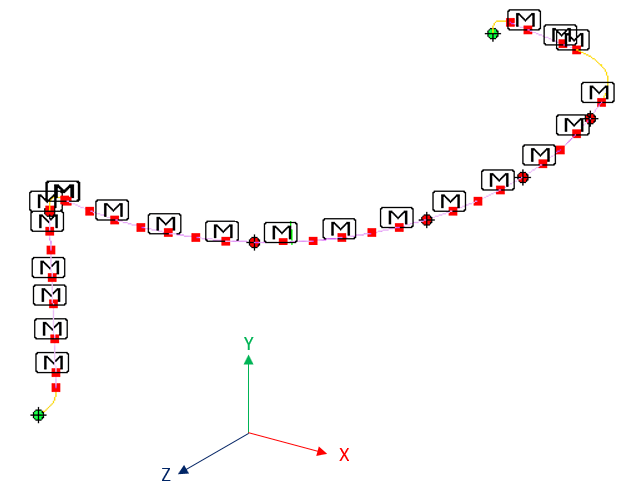

Figure 1: Benchmark 6 diagram

The following table shows the coordinates of each of the points in the pipe:

Knot |

X (m) |

Y (m) |

Z (m) |

PT_1 |

3.20 |

12.29 |

17.93 |

PT_2 |

3.20 |

12.29 |

17.90 |

PT_3 |

3.20 |

13.44 |

16.75 |

PT_4 |

3.20 |

14.43 |

16.75 |

PT_5 |

3.20 |

16.56 |

16.75 |

PT_6 |

3.20 |

18.69 |

16.75 |

PT_7 |

3.20 |

20.39 |

16.75 |

PT_8 |

3.20 |

22.08 |

16.75 |

PT_9 |

3.20 |

23.30 |

16.75 |

PT_10 |

3.20 |

24.52 |

16.75 |

PT_11 |

3.20 |

24.59 |

16.75 |

PT_12 |

4.31 |

25.74 |

16.50 |

PT_13 |

4.42 |

25.74 |

16.48 |

PT_14 |

5.84 |

25.74 |

16.03 |

PT_15 |

7.21 |

25.74 |

15.46 |

PT_16 |

8.53 |

25.74 |

14.77 |

PT_17 |

9.79 |

25.74 |

13.97 |

PT_18 |

10.97 |

25.74 |

13.07 |

PT_19 |

12.07 |

25.74 |

12.06 |

PT_20 |

13.08 |

25.74 |

10.96 |

PT_21 |

13.98 |

25.74 |

9.78 |

PT_22 |

14.78 |

25.74 |

8.52 |

PT_23 |

15.47 |

25.74 |

7.20 |

PT_24 |

16.04 |

25.74 |

5.83 |

PT_25 |

16.49 |

25.74 |

4.41 |

PT_26 |

16.81 |

25.74 |

2.95 |

PT_27 |

17.00 |

25.74 |

1.48 |

PT_28 |

17.07 |

25.74 |

-0.01 |

PT_29 |

17.00 |

25.74 |

-1.50 |

PT_30 |

16.81 |

25.74 |

-2.97 |

PT_31 |

16.49 |

25.74 |

-4.43 |

PT_32 |

16.04 |

25.74 |

-5.85 |

PT_33 |

15.47 |

25.74 |

-7.22 |

PT_34 |

14.78 |

25.74 |

-8.54 |

PT_35 |

13.99 |

25.74 |

-9.79 |

PT_36 |

9.53 |

25.74 |

-11.35 |

PT_37 |

8.78 |

25.74 |

-11.09 |

PT_38 |

6.66 |

25.74 |

-10.36 |

PT_39 |

5.63 |

25.74 |

-10.00 |

PT_40 |

4.55 |

24.59 |

-9.63 |

PT_41 |

4.55 |

24.59 |

-9.63 |

Table 1: Coordinates of pipe nodes

The following table shows the types of elements that make up the pipe:

Element |

Node 1 |

Node 2 |

Type |

Section |

EL_1 |

|

|

Tangent |

1 |

EL_2 |

|

|

Bend |

1 |

EL_3 |

|

|

Tangent |

1 |

EL_4 |

|

|

Tangent |

1 |

EL_5 |

|

|

Tangent |

1 |

EL_6 |

|

|

Tangent |

1 |

EL_7 |

|

|

Tangent |

1 |

EL_8 |

|

|

Tangent |

1 |

EL_9 |

|

|

Tangent |

1 |

EL_10 |

|

|

Tangent |

1 |

EL_11 |

|

|

Bend |

1 |

EL_12 |

|

|

Tangent |

1 |

EL_13 |

|

|

Tangent |

1 |

EL_14 |

|

|

Tangent |

1 |

EL_15 |

|

|

Tangent |

1 |

EL_16 |

|

|

Tangent |

1 |

EL_17 |

|

|

Tangent |

1 |

EL_18 |

|

|

Tangent |

1 |

EL_19 |

|

|

Tangent |

1 |

EL_20 |

|

|

Tangent |

1 |

EL_21 |

|

|

Tangent |

1 |

EL_22 |

|

|

Tangent |

1 |

EL_23 |

|

|

Tangent |

1 |

EL_24 |

|

|

Tangent |

1 |

EL_25 |

|

|

Tangent |

1 |

EL_26 |

|

|

Tangent |

1 |

EL_27 |

|

|

Tangent |

1 |

EL_28 |

|

|

Tangent |

1 |

EL_29 |

|

|

Tangent |

1 |

EL_30 |

|

|

Tangent |

1 |

EL_31 |

|

|

Tangent |

1 |

EL_32 |

|

|

Tangent |

1 |

EL_33 |

|

|

Tangent |

1 |

EL_34 |

|

|

Tangent |

1 |

EL_35 |

|

|

Bend |

1 |

EL_36 |

|

|

Tangent |

1 |

EL_37 |

|

|

Tangent |

1 |

EL_38 |

|

|

Tangent |

1 |

EL_39 |

|

|

Bend |

2 |

EL_40 |

|

|

Tangent |

2 |

Table 2: Type of pipe elements

1.2. Material properties#

The characteristics are as follows:

\(\mathit{YOUNG}=206000\mathit{MPa}\)

\(\mathit{NU}=0.30\)

\(\mathit{RHO}=0\mathit{kg}/m3\)

The mass of the pipe is not considered in this test case.

1.3. Boundary conditions and loads#

1.3.1. Boundary conditions#

In accordance with Figure, this study does not include fixed supports. On the other hand, some points are elastic supports whose characteristics are specified in the following tables:

Knot |

X (m) |

Y (m) |

Z (m) |

Type |

|

RESS_PT10_42_BASE |

0.00 |

0.00 |

0.00 |

-0.19 |

K_T_D_L |

RESS_PT10_43_BASE |

1.83 |

3.69 |

-0.03 |

K_T_D_L |

|

RESS_PT30_50_BASE |

2.78 |

3.69 |

3.69 |

0.92 |

K_T_D_L |

RESS_PT34_51_BASE |

2.75 |

3.71 |

3.00 |

K_T_D_L |

|

RESS_PT1_BASE |

3.20 |

12.29 |

12.29 |

17.93 |

K_ TR_D_L |

RESS_PT20_BASE |

13.08 |

25.74 |

25.74 |

10.96 |

K_ TR_D_L |

RESS_PT26_BASE |

16.81 |

25.74 |

2.95 |

K_ TR_D_L |

|

RESS_PT41_BASE |

4.55 |

24.59 |

-9.63 |

K_ TR_D_L |

Table 3: Coordinates and type of elastic supports

Node |

K local (N/m) |

K X (N/m) |

K Y (N/m) |

K Z (N/m) |

K RX (N/ rad )) ** |

K RY (N/ rad )) ** |

K RZ (N/ rad ) |

||

RESS_PT10_42_BASE |

1.75E+08 |

||||||||

RESS_PT10_43_BASE |

1.75E+08 |

||||||||

RESS_PT30_50_BASE |

3.50E+08 |

||||||||

RESS_PT34_51_BASE |

1.40E+08 |

||||||||

RESS_PT1_BASE |

1.75E+21 |

1.75E+21 |

1.75E+21 |

1.75E+21 |

1.75E+21 |

1.75E+21 |

1.75E+21 |

||

RESS_PT20_BASE |

4.37E+07 |

4.37E+07 |

3.50E+08 |

4.37E+07 |

|||||

RESS_PT26_BASE |

7.87E+07 |

3.50E+07 |

3.50E+08 |

7.87E+07 |

|||||

RESS_PT41_BASE |

1.75E+11 |

1.75E+11 |

1.75E+11 |

1.13E+16 |

1.13E+16 |

1.13E+16 |

1.13E+16 |

1.13E+16 |

Table 4: Stiffers of elastic supports

1.3.2. Loads#

The loads applied to the pipe are as follows:

Point masses in different nodes (identical in all 3 directions);

Earthquake in X, Y, and Z directions. The spectrum is weighted by 1 in all three directions;

Knot |

M ( kg ) |

PT_4 |

1 738.13 |

PT_5 |

954.97 |

PT_6 |

856.02 |

PT_7 |

1 031.15 |

PT_9 |

940.96 |

PT_11 |

691.75 |

PT_12 |

425.56 |

PT_13 |

690.17 |

PT_15 |

1 332.54 |

PT_17 |

1 332.54 |

PT_19 |

1 333.07 |

PT_21 |

1 332.89 |

PT_23 |

1 332.89 |

PT_25 |

1 332.89 |

PT_27 |

1 332.89 |

PT_29 |

1 332.89 |

PT_31 |

1 332.89 |

PT_33 |

1 331.14 |

PT_35 |

1 802.58 |

PT_36 |

1 316.60 |

PT_37 |

678.97 |

PT_38 |

1 843.74 |

Table 5: Values and locations of point masses

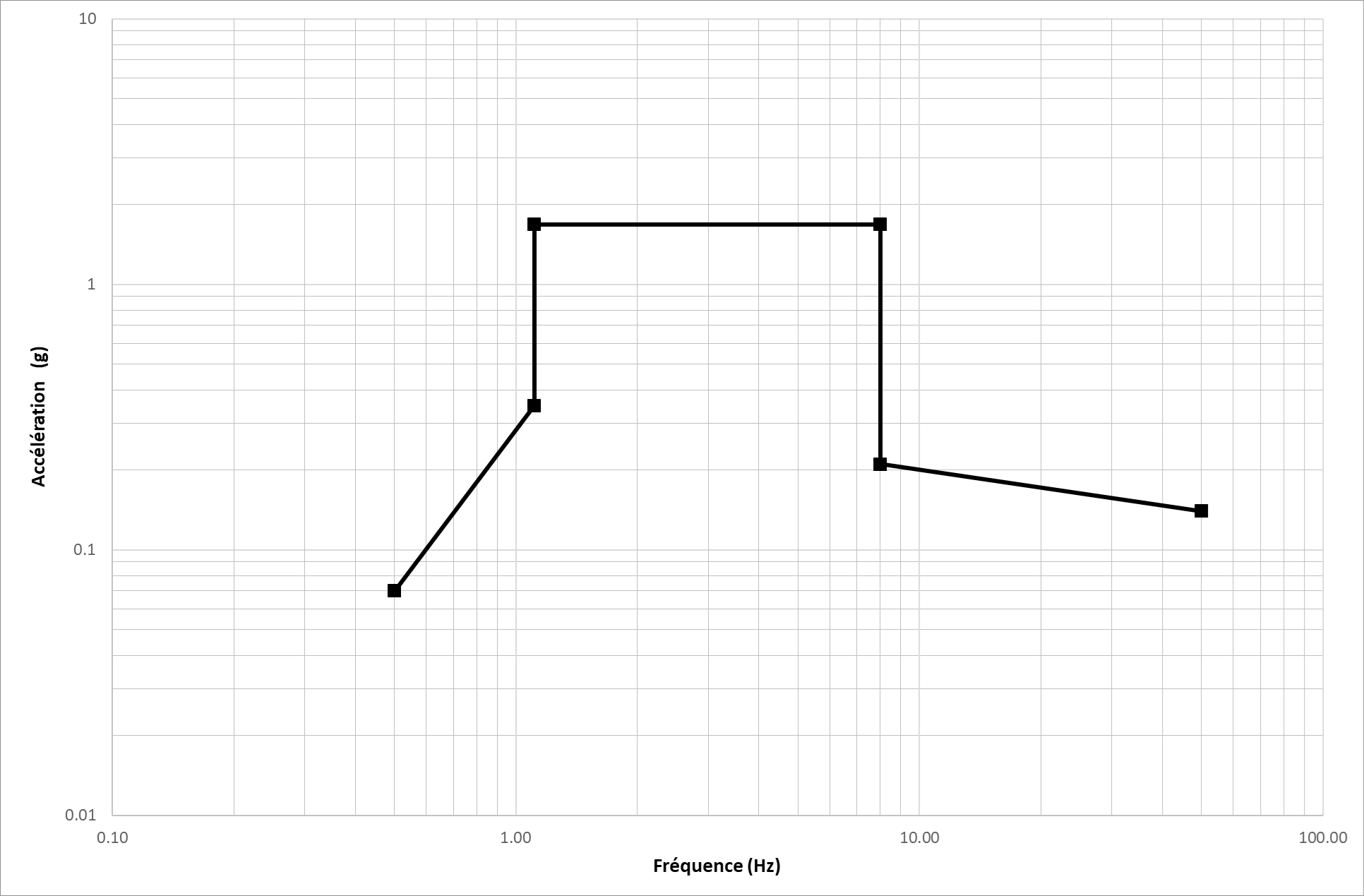

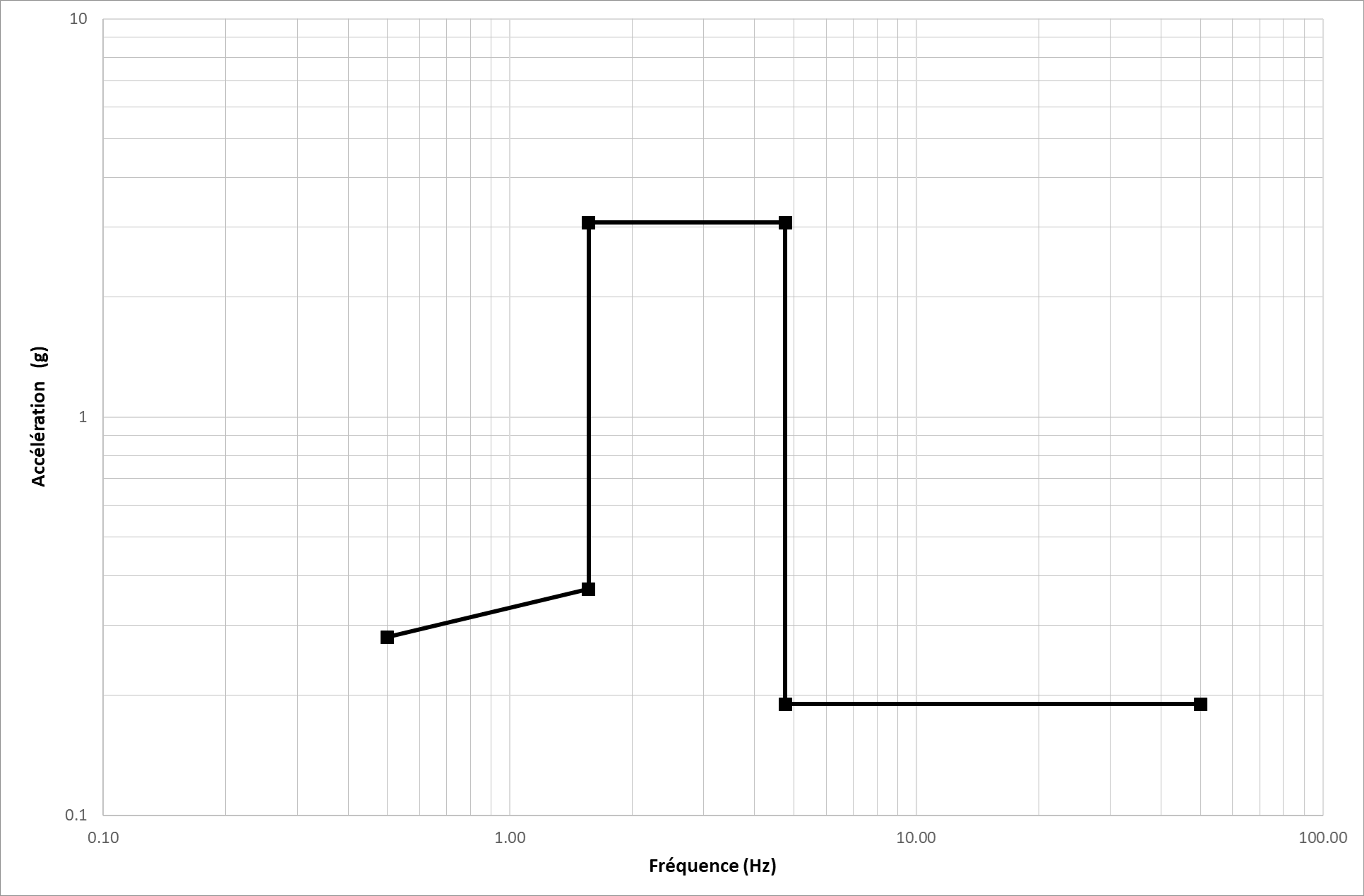

The spectra used for modal analysis are shown in the following figure:

Figure 2: Computational spectrum — X and Z

Figure 3: Computational spectrum - Y