3. Modeling A#

3.1. Characteristics of modeling#

Model A is modelled using elements DIS_T

3.2. Characteristics of the mesh#

Number of knots: 2

Number of meshes: 3 DIS_T to model the mass (M_T_D_N), the stiffness (K_T_D_L) and the shock absorber (A_T_D_L)

3.3. Results#

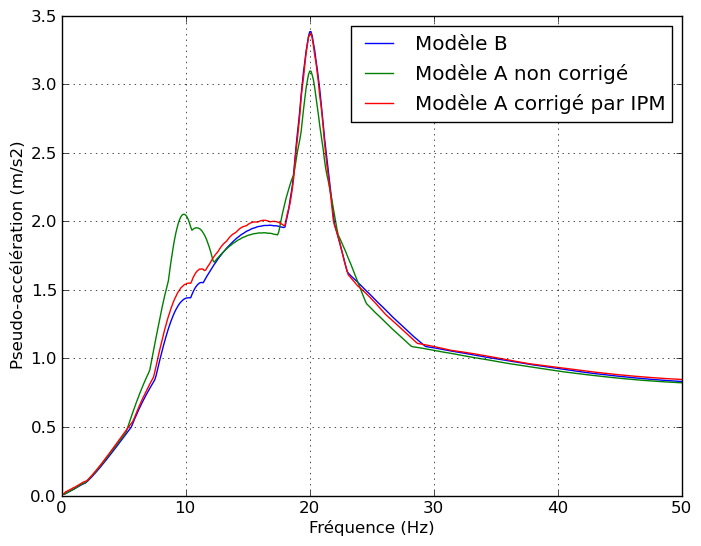

The vertical response spectrum obtained using the macro-command CALC_SPECTRE_IPM from the vertical acceleration of the node N 02 is compared to that obtained using the model B. We are in a case with relative coordinate resolution (single-press loading).

A check of the pseudo_acceleration values is performed for several acceleration values.

Node |

Frequency |

Reference |

Reference Type |

Tolerance |

N02 |

5 |

0.425896 |

“AUTRE_ASTER” |

3% |

N02 |

10 |

1.44050 |

“AUTRE_ASTER” |

3% |

N02 |

15 |

1.93754 |

“AUTRE_ASTER” |

0.1% |

N02 |

20 |

3.39816 |

“AUTRE_ASTER” |

0, 5% |

N02 |

25 |

1.46011 |

“AUTRE_ASTER” |

1% |

N02 |

30 |

1.08058 |

“AUTRE_ASTER” |

1.1% |

N02 |

35 |

1.00117 |

“AUTRE_ASTER” |

0, 9% |

N02 |

40 |

0.929183 |

“AUTRE_ASTER” |

0, 3% |

N02 |

45 |

0.871687 |

“AUTRE_ASTER” |

1% |

N02 |

50 |

0.833936 |

“AUTRE_ASTER” |

1, 9% |

The treatment of the case is also validated in absolute reference, by comparison with the result in relation to a zero training signal.

Finally, we validate the initial correction (CORR_INIT =” OUI “) for which a non-zero initial acceleration is required. To do this, we will shift the training signal slightly in time: \(f(t)=\mathrm{sin}(2\mathrm{\pi }20.(t+0.00001))\). The answer obtained will therefore remain very close to the initial calculation without this delay.