2. Modeling A#

2.1. Characteristics of modeling A#

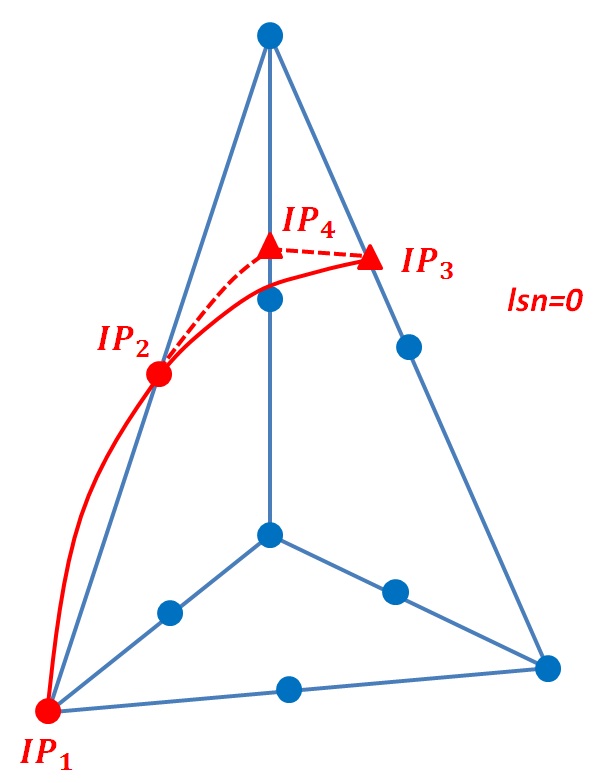

The first cut we’re testing corresponds to the case where one of the edges of TETRA10 sees the lsn cancel out exactly twice, at one of its ends and at its midpoint. An example of this configuration is shown in Figure.

Figure 2.1-a : representation of the cut of modeling A

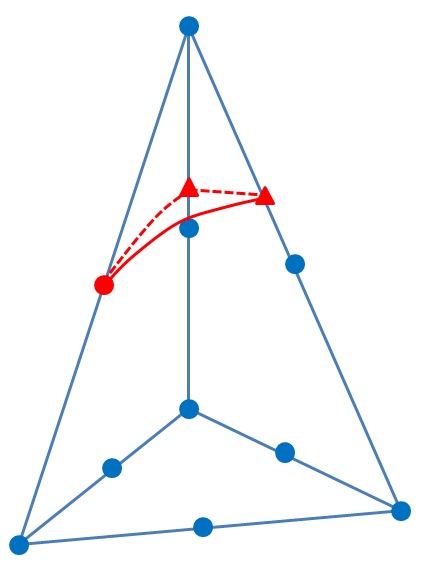

For cutting, we come back to the more classical case represented in Figure, whose sub-tetrahedron cutting is detailed in [R7.02.12].

Figure 2.1-b : : corresponding healthy configuration

2.2. Characteristics of the mesh#

To « find yourself » in this cutting configuration, the lsn is chosen spherical, with a center C (\(\frac{3}{4}\), \(\frac{3}{4}\), \(\frac{1}{4}\)) and with a radius \(R=\frac{\sqrt{(19)}}{4}\)

The edges of the tetrahedron are then intersected by the level set at the following 4 points:

Intersection point |

Coordinates |

IP1 |

(0,0,0) |

IP2 |

(0,0,0.5) |

IP3 |

(\(\frac{3-\sqrt{(5)}}{4}\) ,0, \(\frac{\sqrt{(5)}+1}{4}\)) |

IP4 |

(0, \(\frac{3-\sqrt{(5)}}{4}\), \(\frac{\sqrt{(5)}+1}{4}\)) |

2.3. Tested sizes and results#

After executing command MODI_MODELE_XFEM, we check that the 4 intersection points IP1, IP2, IP3 and IP4 are in group NFISSU and that their position is correct.

Quantities tested |

Reference type |

Reference value |

Tolerance |

COORX IP1 |

“ANALYTIQUE” |

0.0 |

10E-06 |

COORY IP1 |

“ANALYTIQUE” |

0.0 |

10E-06 |

COORZ IP1 |

“ANALYTIQUE” |

0.0 |

10E-06 |

COORX IP2 |

“ANALYTIQUE” |

0.0 |

10E-06 |

COORY IP2 |

“ANALYTIQUE” |

0.0 |

10E-06 |

COORZ IP2 |

“ANALYTIQUE” |

0.5 |

10E-06 |

COORX IP3 |

“ANALYTIQUE” |

0.19098300 |

10E-06 |

COORY IP3 |

“ANALYTIQUE” |

0.0 |

10E-06 |

COORZ IP3 |

“ANALYTIQUE” |

0.80901699 |

10E-06 |

COORX IP4 |

“ANALYTIQUE” |

0.0 |

10E-06 |

COORY IP4 |

“ANALYTIQUE” |

0.19098300 |

10E-06 |

COORZ IP4 |

“ANALYTIQUE” |

0.80901699 |

10E-06 |

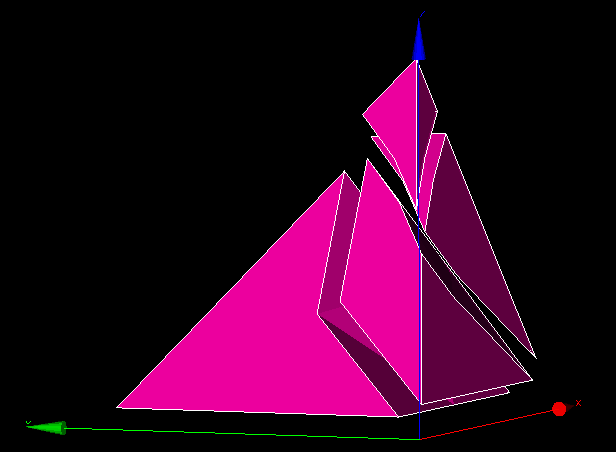

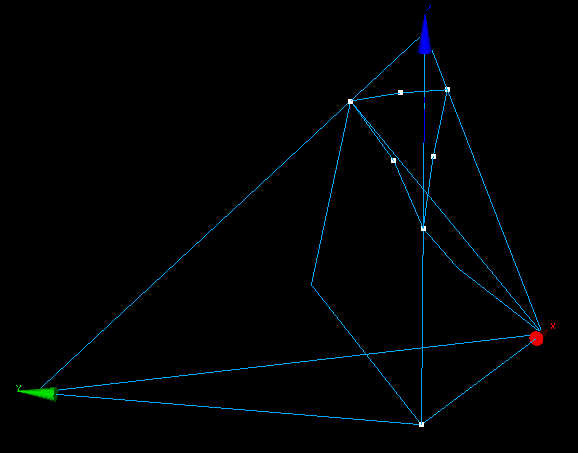

The cut mesh (Figure) was also post-processed using SALOME. The cut obtained is in accordance with expectations, with 4 subtetrahedra that are consistent with the discontinuity.

Figure 2.3-a : A modeling cutting configuration