3. Operands#

3.1. Operands TABLE/TEMPER/DEBIT#

◊ DEBIT = CO (“flow”)

These keywords make it possible to give the name of the concepts coming out of the macro-command, namely

TABLE: a table of 7 columns giving for each time step: the dimension \(z\), the flow, the total pressure (\(\mathrm{Pa}\)), the temperature of the fluid (\(°C\)), the convective exchange coefficient (\({\mathit{W.m}}^{-2.}°{C}^{-1}\)), the name of the crack.

TEMPER: the data structure resulting from the thermal calculation

DEBIT: the flow value (\({\mathit{kg.s}}^{-1}\)) at each time step and for each crack

Notes:

|

3.2. Keyword ETAT_INIT#

♦ EVOL_NOLI = evol_noli ♦ EVOL_THER = evol_ther ♦ NUME_ORDRE = order_number

Keyword used to define the initial state in the context of a continuation of the macro-command.

3.2.1. Operand EVOL_NOLI#

Name of the evol_noli type concept from which the mechanical state will be extracted.

3.2.2. Operand EVOL_THER#

Name of the evol_ther-type concept from which the thermal state will be extracted. This concept will be enriched during the calculation.

3.2.3. Operand NUME_ORDRE#

The initial status to continue the calculation will be defined using the archive number NUME_ORDRE for evol_noli and for evol_ther.

3.3. Operands MODELE_MECA/MODELE_THER#

♦ MODELE_MECA = m_meca

♦ MODELE_THER = m_ther

These keywords make it possible to enter the name of the model (m_meca) whose elements are the subject of mechanical calculation and the name of the model (m_ther) whose elements are the subject of thermal calculation.

3.4. Operand LIST_INST#

♦ LIST_INST = list_inst

List of time steps that correspond to the required calculation times. In case of redistribution, the moments are included in this list.

3.5. Operand CHAM_MATER#

♦ CHAM_MATER = chmat

The name of the material field assigned to the mesh. Attention, this field must include data associated with mechanical behavior and thermal behavior (keyword THER of DEFI_MATERIAU).

3.6. Operand TEMP_INIT#

♦ TEMP_INIT = temp_init

Value of the initial temperature over the entire domain.

3.7. Operand CARA_ELEM#

This keyword allows you to specify the characteristics of the elements of a beam, bar, bar, shell, pipe, discrete element, when they are present in the model. Attention, this keyword is only used for mechanical calculation but is not transmitted for the thermal operator (to avoid any problem with the bars).

3.8. Keyword EXCIT_MECA#

♦ CHARGE = chi ◊ FONC_MULT = fi ◊ TYPE_CHARGE =/ »FIXE_CSTE » / »SUIV » / »DIDI » )

The aim here is to specify the boundary conditions of the mechanical problem, as well as any mechanical loads that apply to the structure. The syntax is identical to that of the EXCIT keyword in STAT_NON_LINE but it is not possible to control a loading. See document [U4.51.03].

3.9. Keyword CONTACT#

The contact conditions between the lips of the crack, which may close during the calculation, are given here. The purpose of this keyword is to avoid the interpenetration of the lips, which can occur as a result of the flow of fluid.

3.10. Keyword EXCIT_THER#

♦ CHARGE = chi ◊ FONC_MULT = fi )

The aim here is to provide information on the boundary conditions of the thermal problem as well as any thermal loads. The syntax is the same as the EXCIT keyword in THER_LINEAIRE.

See document [U4.54.01].

3.11. Keyword COMPORTEMENT#

The aim here is to fill in the law of behavior that will be used to solve the mechanical problem. See document [U4.51.03].

3.12. Keyword NEWTON#

The aim here is to fill in the parameters of Newton’s algorithm to solve the mechanical problem. This keyword is the same as STAT_NON_LINE, so refer to the document [U4.51.03].

3.13. Keyword CONVERGENCE#

The aim here is to fill in the convergence criteria for mechanical calculation. The syntax corresponds to that of STAT_NON_LINE (see document [U4.51.03]).

Note:

It may be necessary to use RESI_GLOB_MAXI rather than RESI_GLOB_RELA , when there is no mechanical loading (otherwise zero effort, so RESI_GLOB_RELA undefined) . |

3.14. Keyword ENERGIE#

This keyword allows you to activate the calculation of the energy balance and its display during the mechanical calculation (see document [R4.09.01]). This balance sheet is stored in the name table PARA_CALC from where it can be extracted using the RECU_TABLE [U4.71.02] command.

3.15. Keyword FISSURE#

♦ FISSURE

This keyword makes it possible to define all the parameters relating to a crack. Multiple occurrences of this keyword are possible if there are several cracks.

3.15.1. Operand GROUP_MA#

♦ GROUP_MA = GMA

Groups of cells defining the lip (s) of the crack. We give the group of the lower and upper lip.

3.15.2. Operands GROUP_NO_ORIG and GROUP_NO_EXTR#

♦ GROUP_NO_ORIG = ogno

♦ GROUP_NO_EXTR = black

Allows you to define the two groups of nodes that define the two ends of the crack in order to orient it.

3.15.3. Operand SECTION#

♦ SECTION =/" ELLIPSE"

/ » RECTANGLE »

The aim here is to define the flow passage section (plane perpendicular to the modeling plane). It can be elliptical or rectangular. One of the dimensions of this section corresponds to the size of the crack in the modeling plane. This is determined at each moment by the macro-command. The other dimension corresponds to the size of the crack outside the modeling plane. This is fixed throughout the calculation and must be entered using the LISTE_COTES_BL and LIST_VAL_BL operands.

3.15.4. Operand RUGOSITE#

♦ RUGOSITE = eps

Absolute wall roughness (in meters). This value only affects the result if the friction is calculated by Crayfish (operand FROTTEMENT >0) and if the flow is no longer laminar.

For friction options \(\mathrm{21,}\mathrm{22,}\mathrm{23,}24\) this is the diameter of the largest aggregate (flow through a crack in concrete).

3.15.5. Operands LISTE_COTES_BL/LISTE_VAL_BL#

◊ LISTE_COTES_BL = LCBL

♦ LISTE_VAL_BL = lvbl

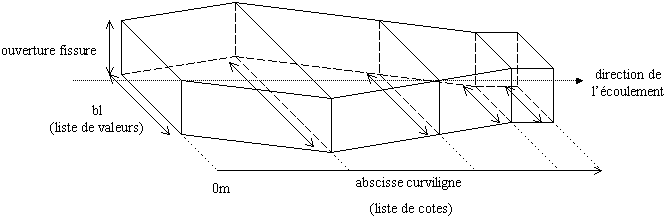

Figure 3.2.5-1: Representation of the crack

To characterize the size of the crack in the non-modelled plane, it is necessary to provide the value of the « small » axis of the elliptical section or the width of the rectangular section at least at 2 points.

LISTE_COTES_BL allows you to fill in the curvilinear abscissa where you give the dimension of the crack and LIST_VAL_BL allows you to give the dimension. If LISTE_COTES_BL is not entered, LISTE_VAL_BL should contain the width of the crack at the entrance and exit of the crack.

3.15.6. Operand ZETA#

♦ ZETA = zeta

Singular pressure loss coefficient at the inlet (dimensionless).

3.15.7. Operand OUVERT_REMANENTE#

♦ OUVERT_REMANENTE = open_rem

Value of the residual opening (in meters) for the Crayfish calculation corresponding to the actual hydraulic opening of the crack when the two lips are in contact. This reflects the fact that, even when the crack is closed, a small amount of fluid will pass through, in particular because of the roughness. This parameter depends on the material: for example, it is in the order of \(10\mu m\) for concrete.

This keyword is therefore taken into account during the hydraulic calculation (Ecrevisse), but not by Code_Aster: it may therefore well happen that the hydraulic calculation is carried out with the residual opening, or that the contact is activated in the mechanical calculation.

3.15.8. Operand TORTUOSITE#

◊ TORTUOSITE = wrong

If the crack is tortuous, it can be assumed that, seen from the fluid, the length of the crack is greater than the thickness of the wall through which it passes. This coefficient, which by default is equal to 1, makes it possible to take this phenomenon into account. The length of the crack will therefore be equal to \(\frac{L}{\mathit{tort}}\) with \(\mathit{tort}\le 1\)

3.15.9. Operand PREFIXE_FICHIER#

◊ PREFIXE_FICHIER = prefix

Allows you to define the name of the Ecrevisse output files in the REPE_OUT folder (curves and text files), and thus to distinguish the files associated with each crack.

3.16. Keyword ECOULEMENT#

♦ ECOULEMENT

This keyword is about defining the nature of the fluid and its characteristics.

3.16.1. Operands PRES_ENTREE/PRES_ENTREE_FO#

♦/PRES_ENTREE = pe

/PRES_ENTREE_FO = fpe

This operand makes it possible to give the total pressure (\(\mathit{Pa}\)) or its evolution over time, upstream of the crack. It should be between \(215\mathrm{.}{10}^{5}\mathit{Pa}\) and \({10}^{5}\mathit{Pa}\).

3.16.2. Operands PRES_SORTIE/PRES_SORTIE_FO#

♦/PRES_SORTIE = pe

/PRES_SORTIE_FO = fpe

This operand makes it possible to give the total pressure (\(\mathit{Pa}\)) or its evolution over time, at the exit of the crack. It should be between \(215\mathrm{.}{10}^{5}\mathit{Pa}\) and \(800\mathit{Pa}\) and be less than the inlet pressure (otherwise there is no flow and the calculation stops).

3.16.3. Operand FLUIDE_ENTREE#

♦ FLUIDE_ENTREE = 1,2,3,4,5 or 6

This operand makes it possible to define the state of the fluid at the entrance to the crack:

1: Subcooled or saturated water;

2: Two-phase fluid;

3: Saturated or superheated steam;

4: Air + superheated steam;

5: Air + saturated steam;

6: Air alone.

Depending on the fluid situation, only some of the following characteristics are required.

3.16.4. Operands TEMP_ENTREE/TEMP_ENTREE_FO#

♦/TEMP_ENTREE = and

/TEMP_ENTREE_FO = party

This operand makes it possible to specify the temperature (\(°C\)) or its evolution over time, prior to the crack. It must be entered if the fluid at the inlet is « Subcooled or saturated water », « Saturated or superheated steam », « Air + superheated steam », or « Air only ».

(operand FLUIDE_ENTREE = 1,3,4, or 6).

3.16.5. Operands TITR_MASS/TITR_MASS_FO#

♦/TITR_MASS = ex

/TITR_MASS_FO = fixed

This operand makes it possible to specify the vapour mass content, or its evolution over time, prior to the crack. It corresponds to the ratio between the mass of steam and the mass of liquid water and steam. It must be entered if the fluid at the inlet is « Two-phase fluid » or « Air + saturated steam » (operand FLUIDE_ENTREE = 2 or 5).

3.16.6. Operands PRES_PART/PRES_PART_FO#

♦/PRES_PART = not

/PRES_PART_FO = fpae

This operand makes it possible to specify the partial air pressure (\(\mathit{Pa}\)) or its evolution over time, upstream of the crack. It must be entered if the fluid at the inlet is « Air + superheated steam » or « Air + saturated steam » (operand FLUIDE_ENTREE =4 or 5).

3.17. Keyword MODELE_ECRE#

♦ MODELE_ECRE

This keyword allows you to enter the models that will be used by Ecrevisse to calculate the flow of the fluid.

3.17.1. Operand IVENAC#

◊ IVENAC = 0 or 1,

When this operand is activated (IVENAC =1), the ECREVISSE calculation is performed taking into account the vena contracta (pressure loss at input). Otherwise (case by default), the calculation will be performed without this modeling option.

3.17.2. Operand ECOULEMENT#

♦ ECOULEMENT =/'SATURATION',

/”GELE”

In the absence of air and in the presence of water (operand FLUIDE_ENTREE =1 or 2), this operand makes it possible to choose between the homogeneous equilibrium model and the « GELE » flow model characterized by a non-zero fraction of metastable liquid.

3.17.3. Operand PRESS_EBULLITION#

Boiling pressure (\(\mathit{Pa}\)) to be provided for the frozen flow model only.

3.17.4. Operand FROTTEMENT#

The aim here is to define how friction is calculated. Valid values are: \(-\mathrm{14,}-\mathrm{12,}-\mathrm{11,}-\mathrm{4,}-\mathrm{3,}-\mathrm{2,}-\mathrm{1,}\mathrm{0,}\mathrm{1,}\mathrm{2,}\mathrm{3,}\mathrm{4,}\mathrm{11,}\mathrm{12,}\mathrm{14,}\mathrm{21,}\mathrm{22,}\mathrm{23,}24\).

The value \(0\) corresponds to a frictionless calculation.

For negative values, the user sets the value of the coefficient of friction for turbulent flows.

For positive values, the friction in turbulent flow is calculated from the roughness coefficient. In particular, options \(\mathrm{21,}\mathrm{22,}\mathrm{23,}24\) correspond to the Greiner and Ramm [Bib.6] friction relationship for flow in a crack in concrete; in this case, the roughness is the diameter of the largest aggregate. In addition, for values greater than \(10\), the law used for laminar flow (friction proportional to the inverse of the Reynolds number) is connected with that for turbulent flow (constant value of the coefficient of friction). Otherwise, a discontinuity is present.

The second number (1,2,3,4) of each option (units) determines the option for calculating dynamic viscosity for two-phase flows, cf. documentation Ecrevisse [Bib.1] [Bib.2] [Bib.3] [Bib.4] [Bib.5].

3.17.5. Operands REYNOLDS_LIM/FROTTEMENT_LIM#

Limit Reynolds coefficient and coefficient of friction imposed for a Reynolds greater than the Reynolds limit.

To be provided only if FROTTEMENT < 0.

3.17.6. Operand TRANSFERT_CHAL#

This operand makes it possible to define whether or not it is desired to take into account the transfer of heat by convection between the fluid and the wall. Valid values are: \(-\mathrm{12,}-\mathrm{11,}-\mathrm{2,}-\mathrm{1,}\mathrm{0,}\mathrm{1,}\mathrm{2,}\mathrm{11,}12\).

The value 0 corresponds to a calculation without heat transfer (adiabatic).

The other values correspond to different options for calculating the convection coefficient (differences only for the laminar regime). Refer to the Ecrevisse documentation.

3.17.7. Operands XMINCH/XMAXCH#

This operator only makes sense in two-phase cases, if TRANSFERT_CHAL < 0. It makes it possible to enter the value of the gas mass titers delimiting the transition zone between the models for calculating the convection coefficient, see Ecrevisse documentation.

3.18. Keyword CONV_CRITERE#

At each moment, the macro-command calculates three criteria for estimating the importance of the changes that occurred between two time steps and thus the validity of the chaining carried out. To calculate these criteria, the user must define reference values for pressure and temperature, allowing the acceptable deviation to be quantified.

\(\begin{array}{c}{e}_{T}=\frac{\mathit{Max}({T}_{t}-{T}_{\text{t-1}})}{{T}_{\text{REF}}}\\ {e}_{P}=\frac{\mathit{Max}({P}_{t}-{P}_{\text{t-1}})}{{P}_{\text{ref}}}\\ {e}_{G}=\sqrt{{e}_{T}^{2}+{e}_{P}^{2}}\end{array}\)

Then, if he wishes, he can activate the redistribution of the time step if the value of the criterion is less than a given value.

However, the experience gained shows that it is better to try to optimize the list of moments than to count on redividing the time step, because Ecrevisse calculations are relatively long.

.

3.18.1. Operand CRITERE#

Allows you to define the nature of the criterion used to manage the time steps in the macro-command. Possible values are:

EXPLICITE: no redistribution regardless of the value of the indicators

TEMP: there will be redistribution based on the value of \({e}_{T}\)

PRES: there will be redistribution based on the value of \({e}_{P}\)

TEMP_PRES: there will be redistribution based on the value of \({e}_{G}\)

3.18.2. Operand TEMP_REF#

Reference temperature for calculating the temperature criterion of the macro-control.

3.18.3. Operand PRES_REF#

Reference pressure for calculating the pressure criterion of the macro-control.

3.18.4. Operand PREC_CRIT#

Value to which we compare the error obtained to activate or not the redistribution of the time step (1 by default). For example for the temperature: \({e}_{T}<\text{PREC\_CRIT}\)

3.18.5. Operand NUME_ORDRE_MIN#

Order number from which the error criterion is taken into account. Convergence is forced on lower order numbers. This operand is often used to start the activation of the error criterion from the second time step and to force convergence on the first step, which is often difficult to process, since sudden loads are imposed at the initial moment.

3.18.6. Operand SUBD_NIVEAU#

Number of times to redistribute the time step allowed. Beyond this value, you no longer cut again and you leave the macro-command.

3.18.7. Operand SUBD_PAS_MINI#

No time below which we no longer cut.

3.19. Keyword CONVERGENCE_ECREVISSE#

3.19.1. Operand KGTEST#

Parameter of the iterative Ecrevisse algorithm.

Must be between \(0\) and \(1.\). Set by default to \(\mathrm{0,5}\), it may be necessary to set a slightly lower value if convergence difficulties on the flow rate are observed.

3.19.2. Operand ITER_GLOB_MAXI#

Maximum number of iterations allowed for calculating the flow rate (400 by default).

3.19.3. Operand CRIT_CONV_DEBI#

Precision used for the convergence of the flow calculation. This is the value against which Ecrevisse tests the max and min flow in its calculation method.

\(\frac{{G}_{\mathit{max}}-{G}_{\mathit{min}}}{G}⩽\text{CRIT\_CONV\_DEBI}\)

By default to \({10}^{\text{-5}}\), values up to \({10}^{\text{-2}}\) improve computation time without losing much precision.

3.20. Operand COURBES#

/ »POSTSCRIPT » / »INTERACTIF »

Allows you to generate or not the Ecrevisse output curves. If the curves are generated, they are stored in the REPE_OUT folder in postscript format (all the times are in the same postscript file). In interactive mode, the curves are displayed for each time step.

3.21. Operand LOGICIEL#

Allows you to specify « hard » the path to find the Ecrevisse executable. At present, only versions 3.2, 3.2.1 and 3.2.2 are compatible with MACR_ECREVISSE. This operand must be filled in or alternatively the VERSION operand must be entered.

3.22. Operand VERSION#

Indicates the version of Ecrevisse used in the pairing. This operand must be filled in or alternatively the LOGICIEL operand must be entered. Now version 3.2.2 is in use. It is the only one that can be entered under the VERSION operand. If you want to use another version (3.2 or 3.2.1), it must be entered under the LOGICIEL operand.

3.23. Operand ENTETE#

Used to give a title to the Ecrevisse calculation.

3.24. Operand IMPRESSION#

When the operand is set to “OUI”, the macro prints a summary table of the Ecrevisse results along the curvilinear abscissa (temperature, pressure, flow, speed, speed, convection coefficient,…).

3.25. Operand INFO#

INFO =1: almost no display.

INFO =2: displays information about the convergence criterion.