4. How the coupling works#

4.1. Principle#

This macro-command was developed in a specific framework: to estimate the flow rates of a crack in a concrete mass modelled in 2D, possibly containing steels modelled in the form of a bar (not taken into account in the thermal calculation). Use in any other context must therefore be done with the greatest care. However, there are in fact 3 nested macro commands, which may allow you to use only a portion of the functionalities.

The algorithm is as follows:

Start of the macro Loop on the list of moments MACR_ECREVISSE .py Thermal and mechanical load recovery Executing THER_LINEAIRE Projection of thermal loading and definition of loads coming from Crayfish Executing STAT_NON_LINE Entry in CALC_ECREVISSE .py Recovering the crack opening (POST_RELEVE_T) Temperature recovery at the edge of a crack Entry in MACR_ECRE_CALC .py Executing ECREVISSE Retrieving the calculated flow and the result tables Extraction and copy of outgoing data (CL, thermal, Crayfish result…) Evaluation of the convergence criterion (temperature and/or pressure error) Possible redistribution of the time step or even stop depending on the conditions Retrieving information and concepts (loading,…) |

The details of the intermediate macrocommands, CALC_ECREVISSE and MACR_ECRE_CALC, are given in the appendix.

4.2. Units#

You can usually do without units in*Code_Aster* while remaining consistent. However, for the purposes of Crayfish, it is important here to respect the system of international units (SI), in particular for lengths (\(m\)), pressures (\(\mathit{Pa}\)), and temperatures (\(°C\)).

4.3. Some tips for use#

The mesh must be in 2 dimensions, and the crack must be meshed explicitly. For the calculation to be of good quality, it is necessary to optimize the mesh so that it is compatible with the phenomena that we want to represent: mechanical loads, thermal loads but also the flow of the fluid. It is therefore important to sufficiently refine the mesh at the edges of the crack in order to see the material heat up. At the entrance of cracks, thermal and hydraulic phenomena are rapid, so there too it is necessary to refine the mesh sufficiently.

Discretization in time is also very important and must be sufficiently detailed, otherwise there will be significant differences in the answers. It is better to try to optimize this list of moments rather than relying solely on the criteria to redefine because this strategy is much more time consuming.

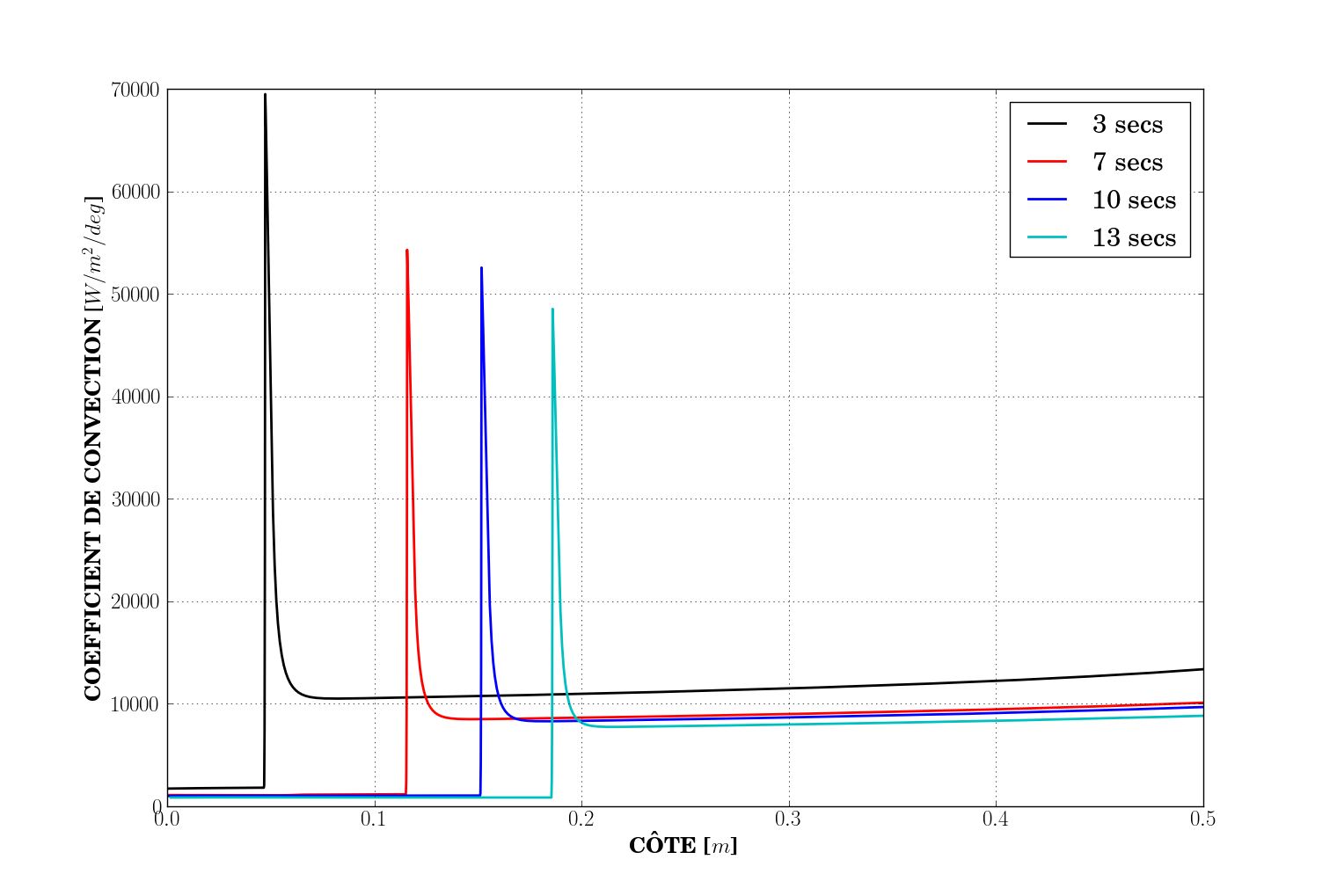

For calculations with condensation of steam on the crack path, the convection coefficient can increase by up to two orders of magnitude upon transition to liquid state. As condensation takes place in an area that is very small in space, the variation in the convection coefficient and therefore in the heat flow transferred to the wall can be very rapid (see the).

This can cause spatial oscillations in the temperature of the massif.

Figure 4.3-1: Convection coefficients at several moments of a calculation with steam condensation.

The macro command may be reentrant. The thermal and mechanical results will be well enriched, but new output tables will be created for the new list of time steps.

Note:

The loads are destroyed at each time step, as well as the material field, the possible post-treatments are in fact limited (displacement, stress and internal variables at the Gauss points) . |