2. The fragile break#

2.1. Mechanisms#

Fragile breakup is a form of sudden breakup. It is generally associated with the phenomenon of cleavage. Cleavage is the complete decohesion of a crystal according to one of its crystallographic planes. The theoretical local constraint necessary for this separation of the crystal lattice \({K}_{\mathit{Ic}}\) is very high, and is expressed as a function of the inter-reticular distance and the surface energy:

where \(E\) is Young’s modulus, \({\mathrm{\gamma }}_{s}\) is the energy that corresponds to the creation of new surfaces and \({d}_{\mathit{hkl}}\) is the inter-reticular distance.

However, the theoretical constraint of separating atomic planes is never reached globally, but it can become so locally thanks to structures that act as stress amplifiers. In the case of steels, it is the numerous defects that play this role, whether due to the plasticity at the crack point (dislocations) or to the composition of the steel (inclusions, cracks) [8].

The breakage of steels by cleavage generally distinguishes between three successive phases: (1) germination, (2) propagation and (3) the crossing of micro-structural barriers (grain boundaries, joints of bainitic packages). Germination corresponds to the development of a microcrack inside healthy metal; it is generally accepted that this step requires a fairly low prior plastic deformation, which causes a stack of dislocations and a singularity of the stresses, and the achievement of a breaking stress limit \({\sigma }_{c}\) (critical threshold). The phenomenon of germination of a micro-crack can be explained by the various plasticity mechanisms (Zener-Stroh, Cottrell, Smith, maclage) listed in [9].

Once the germination stage has passed, a crack can spread under a normal decreasing stress provided it meets a Griffith energy criterion [10]:

with \(W\) representing the rupture energy, and \(r\) the radius of a circular crack.

We obtain an unstable, high-speed propagation of cleavage cracks that can sometimes be slowed down by a relaxation mechanism by sliding dislocations (blunting the cleavage by emission of dislocations) [11].

To be able to propagate in a polycrystal without being stopped by blunting, the crack must cross certain micro-structural barriers (grain boundaries, interphases, etc.) to lead to the ruin of the structure. At the microscopic level, the microstructural entity that controls breakage is not unique and depends heavily on the type of material.

All three steps contribute to the description of the fragile rupture. However, depending on the test temperature and the geometry of the specimen (notched or cracked), one of these steps is preponderant and controls the triggering of brittle failure. Therefore, in order to take into account cleavage mechanisms in a rupture model, only one of these three steps is used to define a failure criterion [12].

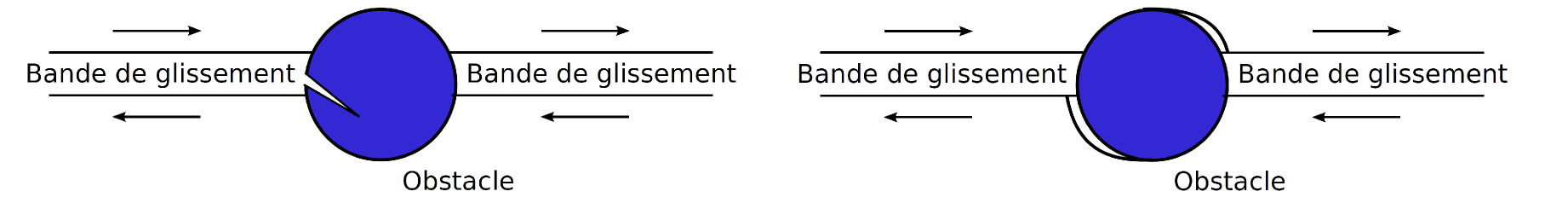

In the case of low-alloy steels at very low temperature (\(T<-160°C\)), rupture is controlled by the priming phase, i.e. the germination of micro-cracks. At higher temperature (\(T>-160°C\)), rupture is controlled by the phase of propagation of micro-cracks initiated on fragile second-phase particles (carbides, manganese sulphides, titanium nitrides) [13, 14]. The amplification of the stresses results from the incompatibilities of deformations between these particles and the matrix. This amplification of the stresses at the head of the dislocation stack can cause: the rupture of the fragile second phase particle (FIG. 1 (a)) or in the case of a weak particle/matrix interface, the decohesion of the interface (FIG. 1 (b)).

Figure 1: (a) initiation of a micro-crack on a fragile second-phase particle, (b) the decohesion of the interface [2]

Studies on ferritic steels in tanks (16 MND5) show that at low temperatures (negative temperatures), it is indeed the stage of propagation of micro-defects (created during the priming phase) in the surrounding ferritic matrix that constitutes the critical step for propagating cleavage [15, 16, 17]. On the other hand, the origin of cleavage cannot be attributed solely to a single microstructural element (a chemical species). The influence of the microstructure of vessel steels is complex since it can involve numerous parameters whose variation induces several consequences [8]. These parameters include grain size, inclusion sizes and defect size distribution. It can therefore be concluded that there is a statistical aspect in terms of the population of faults leading to fragile rupture.

For more details on the influence of microstructure on brittle failure in low-alloy steels of type 16 MND5, we can refer to the work [2, 3, 4].

2.2. Statistical aspect of fragile rupture#

Cleavage is a probabilistic failure mode because the cleavage stress depends on the size distribution of defects and local mechanical fields depend on the local microstructure. The failure begins on the defect for which the critical stress is reached first. However, Ritchie, Knott and Rice [18] (model RKR) postulate that failure only occurs if the critical stress at the crack point is reached over a characteristic distance that represents approximately the size of two grains. Thus breakage by cleavage is conditioned by a characteristic distance and a critical defect size. The RKR model represents the first attempt to relate brittle fracture resistance, expressed by tenacity, to a local failure criterion based on germination mechanisms [8]. This model paved the way for probabilistic models.

Subsequently, the work of Curry and Knott [19] demonstrated that the characteristic distance of the RKR model should not be correlated to the size of the grains but to the distribution of the carbides as well as to their sizes. Thus, for a fixed grain size, at a given test temperature, the toughness of the material increases when the inter-particle distance decreases. This work allowed the introduction of the concept of statistics in fragile rupture models [2]. However, in both models the scale effect and the dispersion of experimental measurements associated with the fragile failure mode are not taken into account.

In order to describe the scale effect and the dispersion of tenacity measures, statistical models were developed starting in the 1980s. Among these models, the most commonly used are those of Beremin [20] and Wallin [21]. These models are based on the weakest link theory and a Weibull statistic [22, 23].

The Beremin model is highly recognized internationally. Beremin’s approach benefits from significant feedback due to both its maturity and the number of researchers and engineers who have tested and modified it. The model makes it possible to take into account numerous effects (small defect, triaxiality, hot preloading) in complex loading situations. Numerous applications have been considered both on specimens and on structures.