1. Introduction of the IPM method#

The problem of taking into account the dynamic coupling between the main and secondary structures in the development of vertical floor spectra is an important point in the dynamic study of structures.

On certain floor strips, equipment is sometimes installed whose total mass compared to that of the floor strip can reach a few percent or even a few tens of percent. However, the interaction between this equipment and the floor band will generally tend to attenuate the amplifications observed, especially when there is a coincidence between the frequency of the floor and the natural frequencies of the equipment installed there.

The investigations carried out in this respect have shown that the equipment/structure mass ratios were likely in some cases to generate a dynamic coupling, referred to as Floor-Material Interaction, and having the main effect, when the natural frequencies of the equipment are close to those of the support, of modifying the dynamic behavior of the floor compared to the « rigid » case.

This document is part of a desire to produce realistic floor spectra taking into account dynamic coupling effects as prescribed by the ASN guides ([1]).

1.1. Method#

Hardware-floor interaction is based on the principle that heavy equipment placed on a floor changes the behavior of the floor. Simplifying hypotheses are used for the modeling of the floor and the equipment. Both will be represented by 1D oscillators in the vertical direction.

The approach described in this note leads to the construction of floor spectra corrected by IPM. These floor spectra are obtained from raw vertical accelerograms (i.e. not taking into account IPM) from a prior transient seismic analysis.

1.2. Consideration of equipment in models#

Before modeling a building, consideration must be given to the consideration of equipment in the mass balance.

Three rules can be identified for taking into account hardware (or secondary structures) in modeling [1]:

Small equipment (a few hundred kilograms) is not taken into account. They are in fact covered by the lump-sum surcharge on the floors;

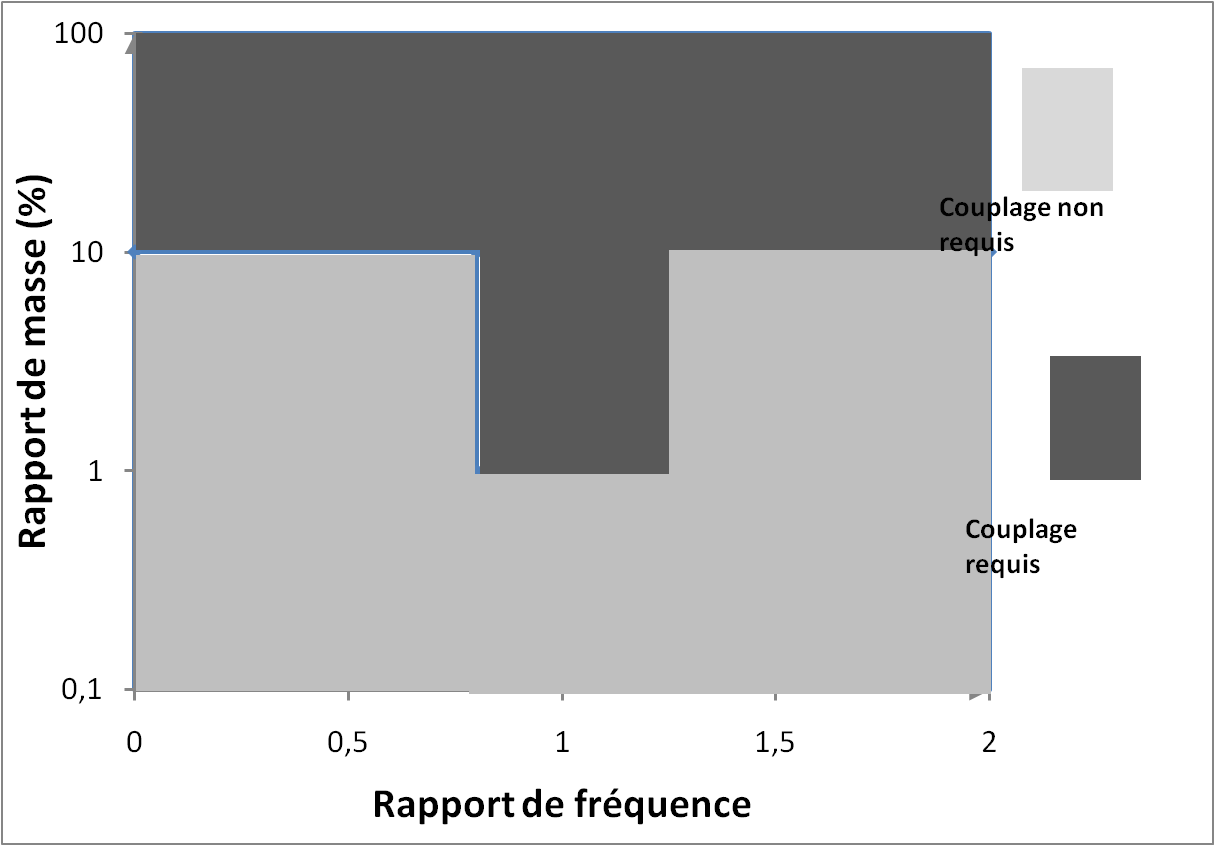

If the mass of the material is low (see Figure 1) compared to that of its support, its dynamic behavior has little influence on the dynamic behavior of the supporting structure. We simply represent this material by masses added to the building model;

For elements of large mass having a sufficiently flexible support, the question of dynamic coupling between the structure and the hardware attached to it then arises.

To summarize, when a material is supposed to be decoupled from the floor, its mass is simply taken into account in the floor model as a distributed or localized added mass. On the other hand, when hardware is assumed to be coupled, it is necessary to take the hardware into account in the global model in order to characterize coupling phenomena. A modal analysis of the equipment placed on the floor panel must be carried out; the main modes must be identified. The hardware is then represented in the global model as simple oscillators.

However, it sometimes happens that some equipment was taken into account as added mass without attaching stiffness to it because their relatively low mass, taken individually, did not justify it or when the dynamic coupling of an equipment had been deemed not significant by the modellers.

The aim of this method is to correct this lack of upstream modeling by taking into account the dynamic coupling between the primary structures and the equipment a posteriori. The equipment concerned may be composed of a sum of small pieces of equipment whose total mass and modal characteristics satisfy the criterion set out in Figure 1 (for example: a row of electrical cabinets) or of a single piece of equipment verifying this same criterion in terms of mass and frequencies.

Figure 1: Coupling/Uncoupling Criteria [2]