2. Modeling A#

2.1. Characteristics of modeling A#

3D Modeling_ HMS. The mesh is composed of 1806 HEXA8 and 204 PENTA6.

The simulation time is \(t\mathrm{=}\mathrm{86,4}s\) (i.e. \(t\mathrm{=}\mathrm{0,001}\mathit{jours}\)) done in 10 steps of time.

2.2. Results#

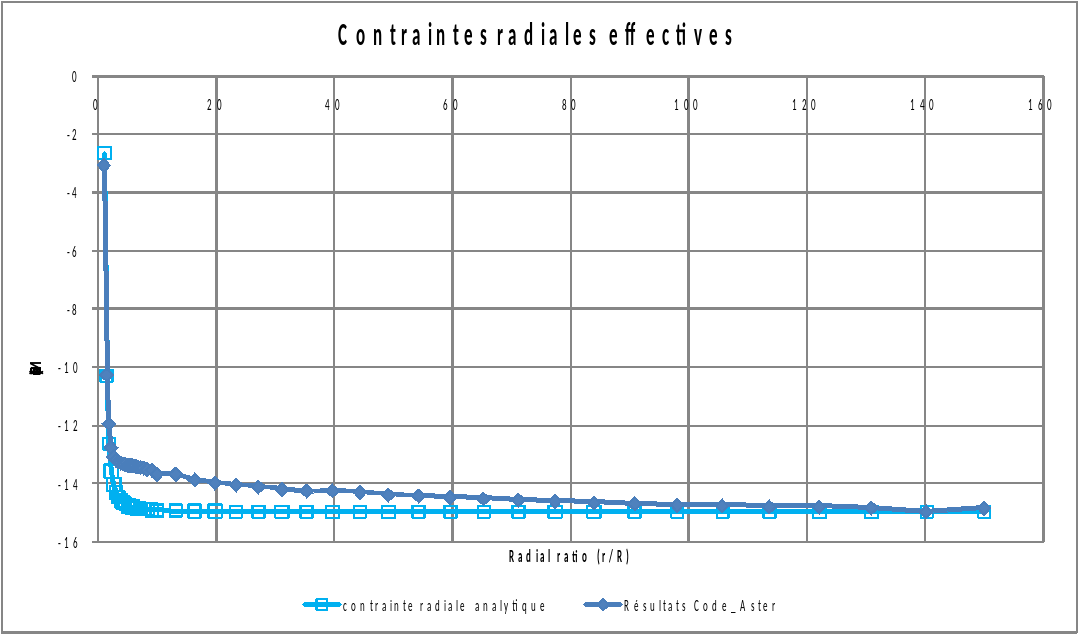

The represents the radial stresses for an angle \(\theta =90°\), i.e. along the \(y\) axis. Modeling and analytical results are shown. Although the overall appearance is the same, there are, however, differences that are logical: first of all, for reasons of calculation time, the mesh is rough here, especially in thickness \(h\). Moreover, we are quite far from infinite geometry and the shear stresses at the edge are not applied. Finally, the effective constraint/total constraint formalism proposed by Abousleiman is slightly different from ours and the comparison requires certain adjustments.

Knowing this, it can be considered that this agreement is entirely acceptable.

Figure 2.2-1 : Modeled geometry

2.3. Tested values#

In accordance with 1, we look at the radial stresses at time \(t\mathrm{=}\mathrm{86,4}s\) (i.e. \(t\mathrm{=}\mathrm{0,001}\mathit{jours}\)).

\(N°\) NODE |

\(\mathrm{COOR}\text{\_}X\) |

|

|

Reference \({\sigma }_{r}(\mathrm{MPa})\) |

Aster \(\mathrm{SIYY}(\mathrm{MPa})\) |

Tolerance \((\text{\%})\) |

||

2286 |

0 |

|

|

|

|

|

||

2582 |

0 |

|

|

|

|

|