1. Reference problem#

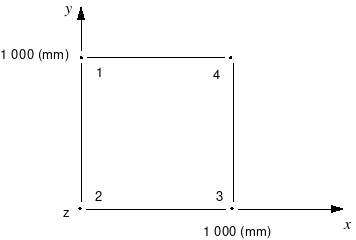

1.1. Geometry#

1.2. Material properties#

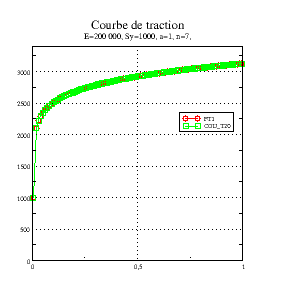

The material obeys a law of behavior in large plastic deformations with isotropic work hardening defined by a traction curve (point by point or power law).

The tensile curve is given in the plane logarithmic deformation - rational stress.

\({l}_{o}\) and \(l\) are, respectively, the initial length and the current length of the useful part of the test piece.

\({S}_{o}\) and \(S\) are, respectively, the initial and current surfaces. Between temperatures \(20°C\) and \(120°C\), the characteristics are interpolated linearly.

1.3. Boundary conditions and loads#

The bar, of initial length \({l}_{o}\), locked in the direction \(\mathrm{Ox}\) on the face [1,2] is subjected to a uniform temperature \(T\) and to a mechanical tensile movement \({u}^{\text{meca}}\) on the face [3, 4]. The loading sequences are as follows:

Y

X

Reference temperature: \({T}_{\text{réf}}\mathrm{=}20°C\).

Note:

The mechanical displacement is measured from the configuration deformed by thermal loading ( \(t\mathrm{=}\mathrm{1s}\) ). To get the total displacement, you must therefore add the thermal displacement obtained to the time \(t\mathrm{=}\mathrm{1s}\) .