1. Reference problem#

1.1. Geometry#

The geometry generated automatically in the macro command SIMU_POINT_MAT [U4.51.12] is unique and simple: it is a tetrahedron with side 1, at whose nodes linear relationships are applied to obtain a homogeneous state of stress and deformation.

1.2. Material properties#

Material characteristics are defined using the DEFI_MATERIAU command. The elastic characteristics are:

\(E=32000\mathrm{MPa}\) (except for D-modeling, see table below)

\(\nu =0.2\),

The other parameters describing the laws were chosen from Code_Aster test cases. The following table summarizes all the Code_Aster laws considered and the associated parameters:

Modeling |

Code_Aster laws of behavior |

parameters retained |

test used for the choice of parameters |

A |

BETON_RAG |

COMP_BETON = “ENDO_FLUA”,

|

Unrealistic values, for the purposes of the computer verification test. |

B |

BETON_UMLV

|

K_RS = 2.0E5 (MPa)

|

Parameters identical to test SSNV163A |

C |

BETON_BURGER

|

K_RS = 2.0E5 (MPa)

|

Parameters identical to test SSNV163D |

D |

ENDO_LOCA_EXP

|

E= 34129 (Mpa)

|

Parameters identical to test SSNV261A |

1.3. Boundary conditions and loads#

1.3.1. Characteristics of the loading path#

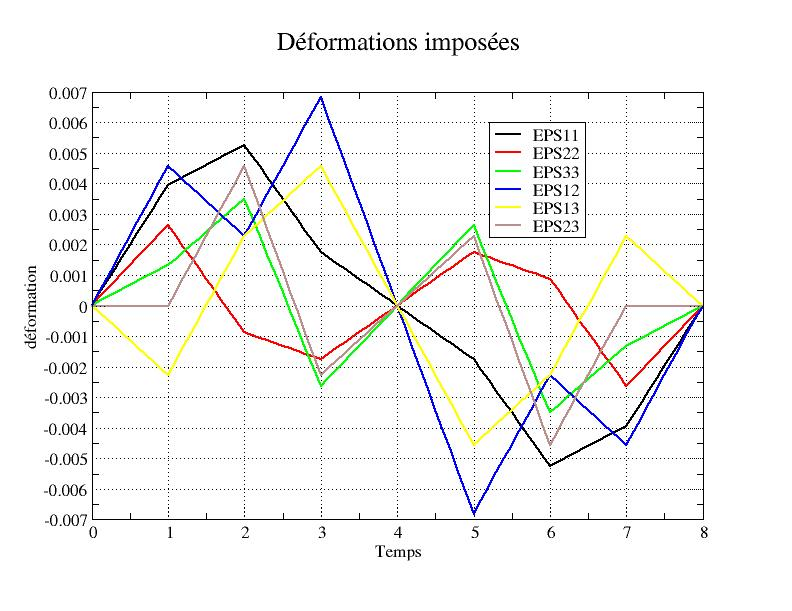

The proposed loading causes each component of the tensor to vary in a decoupled manner from the deformations in successive steps. A cyclic charge-discharge path is proposed by covering the states of traction and compression as well as an inversion of the signs of shear in order to test a wide range of values.

Schematically, it follows a course on 8 segments \(\mathrm{[}O\mathrm{-}A\mathrm{-}B\mathrm{-}C\mathrm{-}O\mathrm{-}C’\mathrm{-}B’\mathrm{-}A’\mathrm{-}O\mathrm{]}\) where the second part of the path \(\mathrm{[}O\mathrm{-}C’\mathrm{-}B’\mathrm{-}A’\mathrm{-}O\mathrm{]}\) is symmetric with respect to the origin of the first \(\mathrm{[}O\mathrm{-}A\mathrm{-}B\mathrm{-}C\mathrm{-}O\mathrm{]}\).

1.3.2. Application of requests#

We come back to the study of a material point (using the macro-command SIMU_POINT_MAT [U4.51.12]) by stressing an element in a homogeneous manner by imposing in \(\mathrm{3D}\), the 6 components of the deformation tensor:

\(\stackrel{ˉ}{\varepsilon }\mathrm{=}\left[\begin{array}{ccc}{\varepsilon }_{\mathit{xx}}& {\varepsilon }_{\mathit{xy}}& {\varepsilon }_{\mathit{xz}}\\ {\varepsilon }_{\mathit{xy}}& {\varepsilon }_{\mathit{yy}}& {\varepsilon }_{\mathit{yz}}\\ {\varepsilon }_{\mathit{xz}}& {\varepsilon }_{\mathit{yz}}& {\varepsilon }_{\mathit{zz}}\end{array}\right]\)

For a more general description, the imposed deformation tensor will be decomposed into a hydrostatic and deviatoric part on shear bases:

\(\stackrel{ˉ}{\varepsilon }\mathrm{=}\left[\begin{array}{ccc}{\varepsilon }_{\mathit{xx}}& {\varepsilon }_{\mathit{xy}}& {\varepsilon }_{\mathit{xz}}\\ {\varepsilon }_{\mathit{xy}}& {\varepsilon }_{\mathit{yy}}& {\varepsilon }_{\mathit{yz}}\\ {\varepsilon }_{\mathit{xz}}& {\varepsilon }_{\mathit{yz}}& {\varepsilon }_{\mathit{zz}}\end{array}\right]\mathrm{=}p\left[\begin{array}{ccc}1& 0& 0\\ 0& 1& 0\\ 0& 0& 1\end{array}\right]+{d}_{1}\left[\begin{array}{ccc}1& 0& 0\\ 0& \mathrm{-}1& 0\\ 0& 0& 1\end{array}\right]+{d}_{2}\left[\begin{array}{ccc}0& 0& 0\\ 0& 1& 0\\ 0& 0& \mathrm{-}1\end{array}\right]+\left[\begin{array}{ccc}0& {\varepsilon }_{\mathit{xy}}& {\varepsilon }_{\mathit{xz}}\\ {\varepsilon }_{\mathit{xy}}& 0& {\varepsilon }_{\mathit{yz}}\\ {\varepsilon }_{\mathit{xz}}& {\varepsilon }_{\mathit{yz}}& 0\end{array}\right]\) in \(\mathrm{3D}\)

1.3.3. Description of the imposed deformation path#

The path applied is described in the table below, the deformation values applied are calibrated with respect to the elastic modulus:

Segment number |

1 |

2 |

2 |

3 |

3 |

3 |

4 |

5 |

6 |

7 |

8 |

Segment |

\(O-A\) |

|

|

|

|

|

|

|

|||

\({\varepsilon }_{\mathit{xx}}\mathrm{\times }E\) |

787.5 |

1050 |

1050 |

350 |

350 |

0 |

-350 |

-1050 |

-787.5 |

0 |

|

\({\varepsilon }_{\mathit{yy}}\mathrm{\times }E\) |

525.0 |

-175 |

-175 |

-350 |

-350 |

175 |

525 |

0 |

|||

\({\varepsilon }_{\mathit{zz}}\mathrm{\times }E\) |

262.5 |

700 |

700 |

-525 |

-525 |

525 |

-700 |

-262.5 |

0 |

||

\({\varepsilon }_{\mathit{xy}}\mathrm{\times }E\mathrm{/}(1+\nu )\) |

700 |

350 |

350 |

1050 |

1050 |

-1050 |

-350 |

-700 |

0 |

||

\({\varepsilon }_{\mathit{xz}}\mathrm{\times }E\mathrm{/}(1+\nu )\) |

-350 |

350 |

350 |

700 |

700 |

0 |

-700 |

700 |

0 |

||

\({\varepsilon }_{\mathit{yz}}\mathrm{\times }E\mathrm{/}(1+\nu )\) |

0 |

700 |

-350 |

-350 |

0 |

350 |

-700 |

0 |

0 |

||

\(P\) |

525 |

525 |

525 |

-175 |

-175 |

-525 |

-525 |

0 |

|||

\(\mathrm{d1}\) |

262.5 |

525 |

525 |

525 |

0 |

-525 |

-525 |

-262.5 |

0 |

||

\(\mathrm{d2}\) |

262.5 |

-175 |

-175 |

350 |

350 |

0 |

-350 |

175 |

-262.5 |

0 |

This path is illustrated by the following graph:

1.4. Initial conditions#

Zero stresses and deformations.