1. Reference problem#

1.1. Geometry#

The geometry (generated automatically in the macro command SIMU_POINT_MAT [U4.51.12]) is unique and simple: in \(\mathrm{3D}\) it is a tetrahedron with side 1, and in \(\mathrm{2D}\) it is a triangle with side 1, at whose nodes linear relationships are applied to obtain a state of homogeneous stress and deformation.

1.2. Material properties#

Material characteristics are defined for each behavior using the DEFI_MATERIAU command. The elastic characteristics and the elastic limit selected are those of standard 16 MND5 steel:

\(E=200000\mathrm{MPa}\), \(\nu =0.3\), \({\sigma }_{y}=437\mathrm{MPa.}\)

The other parameters describing the laws were chosen from Code_Aster test cases. The following two tables summarize all the Code_Aster laws considered and the associated parameters

Model. |

viscoplastic laws of ASTER |

parameters retained |

test selected for the choice of parameters |

A |

LEMAITRE |

m = 5.6

Kinv=1/K= 3.2841e-4

n = 11

|

Test ASTER SSNA01A |

B |

VISC_CIN1_CHAB |

SY = 437.0;

Rinf = 758.0;

b = 2.3;

Cinf = 63767.0

Gamma0 = 341.0

1/m = 0

Kinv=1/K= 3.2841e-4

.. code::

n = 11

|

work hardening: data 16 MND5 other parameters: ssnv101c |

C |

VISC_CIN2_CHAB |

SY = 437.0;

Rinf = 758.0;

b = 2.3;

C1inf = 63767.0/2.0

C2inf = 63767.0/2.0

Gam1 = 341.0

Gam2 = 341.0

1/m = 0

1/K= 3.2841e-4

n = 11

|

Crouching data 16 MND5 other parameters ssnv101c

|

D |

VISC_ENDO_LEMA |

SY=0.0

N=12.0

UN_SUR_M=1/9.0

UN_SUR_K=1/2110.0

R_D=6.3

A_D=3191.0

|

|

E |

VISC_TAHERI |

SY = 437.0; Sinf = 758.0;

alpha = 0.3;

m = 0.1;

a = 312.0;

b = 30.0;

c1 = -0.012;

cinf = 0.065

|

Test ASTER SSNP101B |

F |

VISC_ISOT_LINE |

SY=437 MPa, DSY =2024 Mpa

|

SSNL129 test for part VISC_SINH

|

G |

VISC_ISOT_TRAC |

tensile curve at 100°C of 16 MND5

|

SSNL129 test for part VISC_SINH

|

H |

VISC_CIN2_MEMO |

R0=SY = 437.0;

Q0 = 758.0-437.0;

Qm=Q0+100

Mu=10

Eta=0.5

b = 2.3;

C1inf = 63767.0/2.0

C2inf = 63767.0/2.0

Gam1 = 341.0

Gam2 = 341.0

1/m =0

1/K= 3.2841e-4

n = 11

|

Cinematic choice X1+X2= Xde VMIS_CIN1_CHAB.

|

I |

VISCOCHAB |

SY = 437.0;

Rinf = 758.0;

b = 2.3;

C1inf = 63767.0/2.0

C2inf = 63767.0/2.0

Gam1 = 341.0

Gam2 = 341.0

1/m = 0

1/K= 3.2841e-4

n = 11

Q0 = 758.0-437.0;

Qm=Q0+100

Mu=10

Eta=0.5

|

Work harden:Data 16 MND5 other parameters ssnv101c

|

J |

MONOCRISTAL |

viscoplastic laws of ASTER |

Plastic parameters from SSNV171.Orthotropic parameters from SSLV120 |

K |

VMIS_JOHN_COOK

|

YOUNG = 124000.e6; |

|

L |

HAYHURST

|

YOUNG = 145000. ;

|

|

1.3. Boundary conditions and loads#

1.3.1. Characteristics of loading paths#

Two loading paths have been defined to deal with cases \(\mathrm{3D}\) and \(\mathrm{2D}\) plan. They are common to all laws of behavior. Each of them meets the following criteria:

an accumulated plastic deformation, \(p\), from 4 to \(\text{5\%}\) over the entire path,

an increase of \(1\text{\%}\) in the cumulative plastic deformation \(p\) during a portion of the trip,

in the presence of viscosity, a deformation stress rate of 10-3, 10-4 and \({10}^{-5}{\text{s}}^{-1}\) respectively. These were evaluated approximately by considering an equivalent deformation of \(5\text{\%}\) over the entire journey: i.e. travel times of 50, 500 and 5000 seconds respectively for \(\text{v1}\), \(\text{v2}\) and \(\text{v3}\). The tests returned correspond to a speed of \({10}^{-5}{\text{s}}^{-1}\).

This calibration was carried out on law VMIS_ISOT_LINE, then carried over to the other laws.

The proposed loading causes each component of the deformation tensor to vary in a decoupled manner by successive step. A cyclic load-discharge path is proposed by covering the states of traction and compression as well as an inversion of the signs of shear in order to test a wide range of values.

Schematically, it follows a course on 8 segments \(\text{[O-A-B-C-O-C’-B’-A’-O]}\) where the second part of the path \(\text{[O-C’-B’-A’-O]}\) is symmetric with respect to the origin of the first \(\text{[O-A-B-C-O]}\).

1.3.2. Application of requests#

We come back to the study of a material point (using the macro-command SIMU_POINT_MAT [U4.51.12]) by soliciting an element in a homogeneous manner by imposing:

in \(\mathrm{3D}\), the 6 components of the deformation tensor:

\(\stackrel{ˉ}{\varepsilon }=\left[\begin{array}{ccc}{\varepsilon }_{\mathrm{xx}}& {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{xz}}\\ {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{yy}}& {\varepsilon }_{\mathrm{yz}}\\ {\varepsilon }_{\mathrm{xz}}& {\varepsilon }_{\mathrm{yz}}& {\varepsilon }_{\mathrm{zz}}\end{array}\right]\)

in \(\mathrm{2D}\) the three components of the tensor

\(\stackrel{ˉ}{\varepsilon }=\left[\begin{array}{cc}{\varepsilon }_{\mathrm{xx}}& {\varepsilon }_{\mathrm{xy}}\\ {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{yy}}\end{array}\right]\)

For a more general description, the imposed deformation tensor will be decomposed into a hydrostatic and deviatoric part on shear bases:

\(\stackrel{ˉ}{\varepsilon }=\left[\begin{array}{cc}{\varepsilon }_{\mathrm{xx}}& {\varepsilon }_{\mathrm{xy}}\\ {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{yy}}\end{array}\right]=p\left[\begin{array}{cc}1& 0\\ 0& 1\end{array}\right]+d\left[\begin{array}{cc}1& 0\\ 0& -1\end{array}\right]+{\varepsilon }_{\mathrm{xy}}\left[\begin{array}{cc}0& 1\\ 1& 0\end{array}\right]\) in \(\mathrm{2D}\),

\(\stackrel{ˉ}{\varepsilon }=\left[\begin{array}{ccc}{\varepsilon }_{\mathrm{xx}}& {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{xz}}\\ {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{yy}}& {\varepsilon }_{\mathrm{yz}}\\ {\varepsilon }_{\mathrm{xz}}& {\varepsilon }_{\mathrm{yz}}& {\varepsilon }_{\mathrm{zz}}\end{array}\right]=p\left[\begin{array}{ccc}1& 0& 0\\ 0& 1& 0\\ 0& 0& 1\end{array}\right]+{d}_{1}\left[\begin{array}{ccc}1& 0& 0\\ 0& -1& 0\\ 0& 0& 0\end{array}\right]+{d}_{2}\left[\begin{array}{ccc}0& 0& 0\\ 0& 1& 0\\ 0& 0& -1\end{array}\right]+\left[\begin{array}{ccc}0& {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{xz}}\\ {\varepsilon }_{\mathrm{xy}}& 0& {\varepsilon }_{\mathrm{yz}}\\ {\varepsilon }_{\mathrm{xz}}& {\varepsilon }_{\mathrm{yz}}& 0\end{array}\right]\) in 3D.

1.3.3. Description of the imposed deformation path in 2D#

The path applied is described in the table below, the deformation values are calibrated with respect to the elastic modulus:

time |

1 |

2 |

3 |

3 |

3 |

4 |

5 |

6 |

7 |

8 |

Charging point |

\(A\) |

|

|

|

|

|

|

|

||

\(E\mathrm{.}{\varepsilon }_{\mathrm{xx}}\) |

675 |

1350 |

1350 |

1350 |

0 |

-1350 |

-1350 |

-675 |

0 |

|

\(E\mathrm{.}{\varepsilon }_{\mathrm{yy}}\) |

675 |

450 |

450 |

1350 |

1350 |

0 |

-1350 |

-450 |

-675 |

0 |

\(\frac{E}{(1+\nu )}{\varepsilon }_{\mathrm{xy}}\) |

450 |

180 |

180 |

0 |

0 |

0 |

-180 |

-450 |

0 |

|

\(p\) |

675 |

900 |

900 |

1350 |

-1350 |

-900 |

-675 |

0 |

||

\(d\) |

0 |

0 |

0 |

450 |

450 |

0 |

0 |

0 |

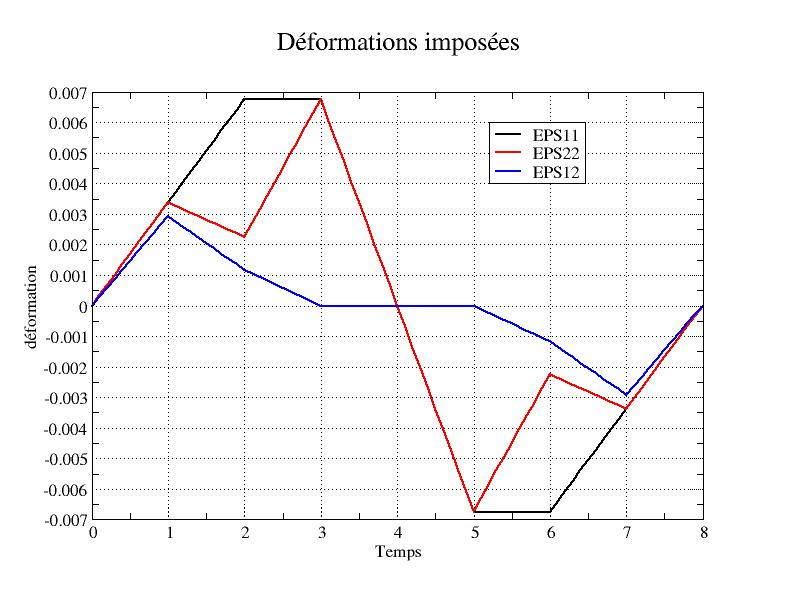

This path is illustrated by the following graph:

1.3.4. Description of the imposed deformation path in 3D#

The path applied is described in the table below, the deformation values applied are calibrated with respect to the elastic modulus:

Segment number |

1 |

2 |

2 |

3 |

3 |

3 |

4 |

5 |

6 |

7 |

8 |

Segment |

\(0-A\) |

|

|

|

|

|

|

|

|||

\(E\mathrm{.}{\varepsilon }_{\mathrm{xx}}\) |

787.5 |

1050 |

1050 |

350 |

350 |

0 |

-350 |

-1050 |

-787.5 |

0 |

|

\(E\mathrm{.}{\varepsilon }_{\mathrm{yy}}\) |

525.0 |

-175 |

-175 |

-350 |

-350 |

175 |

525 |

0 |

|||

\(E\mathrm{.}{\varepsilon }_{\mathrm{zz}}\) |

262.5 |

700 |

700 |

-525 |

-525 |

525 |

-700 |

-262.5 |

0 |

||

\(\frac{E}{(1+\nu )}{\varepsilon }_{\mathrm{xy}}\) |

700 |

350 |

350 |

1050 |

1050 |

-1050 |

-350 |

-700 |

0 |

||

\(\frac{E}{(1+\nu )}{\varepsilon }_{\mathrm{xz}}\) |

-350 |

350 |

350 |

700 |

700 |

0 |

-700 |

700 |

0 |

||

\(\frac{E}{(1+\nu )}{\varepsilon }_{\mathrm{yz}}\) |

0 |

700 |

-350 |

-350 |

0 |

350 |

-700 |

0 |

0 |

||

\(p\) |

525 |

525 |

525 |

-175 |

-175 |

-525 |

-525 |

0 |

|||

\({d}_{1}\) |

262.5 |

525 |

525 |

525 |

0 |

-525 |

-525 |

-262.5 |

0 |

||

\({d}_{2}\) |

262.5 |

-175 |

-175 |

350 |

350 |

0 |

-350 |

175 |

-262.5 |

0 |

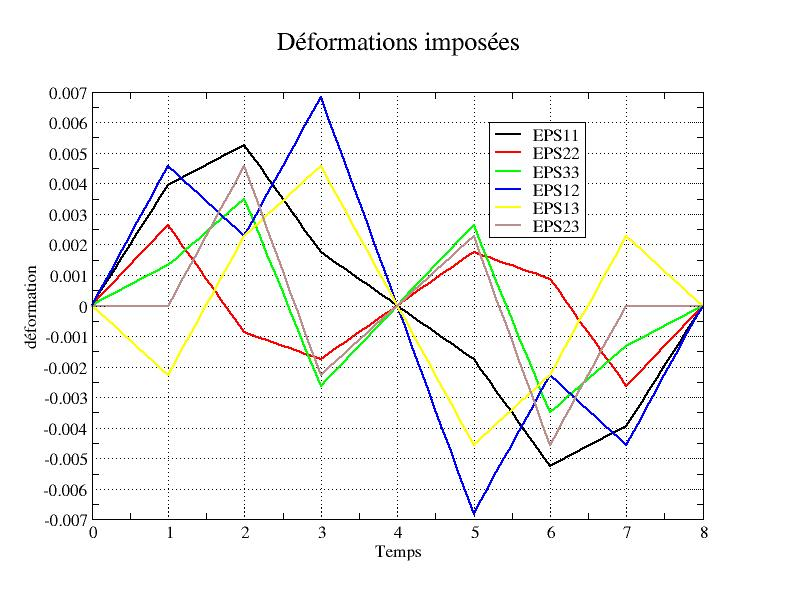

This path is illustrated by the following graph:

1.4. Initial conditions#

Zero stresses and deformations.