1. Reference problem#

1.1. Geometry#

The geometry (generated automatically in the macro command SIMU_POINT_MAT [U4.51.12]) is unique and simple: in 3D it is a tetrahedron on side 1, and in 2D it is a triangle on side 1, at whose nodes linear relationships are applied to obtain a state of homogeneous stress and deformation.

1.2. Material properties#

Material characteristics are defined for each behavior using the DEFI_MATERIAU command. The elastic and isotropic work-hardening characteristics selected are those of standard \(\mathrm{16MND5}\) steel:

\(E=200000\mathrm{MPa}\),

\(\nu =0.3\),

\({\sigma }_{y}=437\mathrm{MPa}\).

The other parameters describing the laws were chosen based on the ASTER test cases. The following two tables summarize all the laws of Code ASTER considered and the associated parameters:

Fashionable. |

Lois Code_Aster |

Parameters retained |

Criteria used for the choice of parameters |

A |

VMIS_ISOT_LINE

|

\(\mathrm{SY}=437\mathrm{MPa}\), \(\mathrm{DSY}=\mathrm{2024MPa}\) |

Material data \(\mathrm{16MND5}\) |

B |

VMIS_ISOT_TRAC

|

Traction curve at \(100°C\) from \(16\mathrm{MND5}\) |

Material data \(\mathrm{16MND5}\) |

C |

VMIS_CINE_LINE

|

\(\mathrm{SY}=437\mathrm{MPa}\), \(\mathrm{DSY}=\mathrm{2024MPa}\) |

Material data \(\mathrm{16MND5}\) |

D |

VMIS_ECMI_LINE

|

\(\mathrm{SY}=437\mathrm{MPa}\), \(\mathrm{DSY}=\mathrm{2024MPa}\) \({C}_{\mathrm{PRAG}}=1486.9\). |

Material data \(\mathrm{16MND5}\) |

E |

VMIS_ECMI_TRAC

|

Traction curve at \(100°C\) from \(16\mathrm{MND5}\) \({C}_{\mathrm{PRAG}}=1486.9\). |

Material data \(\mathrm{16MND5}\) |

F |

VMIS_CIN1_CHAB

|

\(\mathrm{SY}=437.0\);

|

work hardening: \(\mathrm{données16MND5}\) other parameters: ssnv101c |

G |

VMIS_CIN2_CHAB

|

\(\mathrm{SY}=437.0\);

|

|

H |

VMIS_ISOT_PUIS

|

\(\mathrm{SY}=437.0\);

|

|

J |

MOHR_COULOMB

|

\(E=\mathrm{619,3}\mathit{MPa}\)

|

Hostun sand |

K |

MohrCoulombAS

|

\(E=619.3\mathit{MPa}\)

|

Hostun sand |

L |

NLH_CSRM

|

YoungModulus=7.0E9

|

Fictional |

1.3. Boundary conditions and loads#

1.3.1. Characteristics of loading paths#

Two loading paths have been defined to deal with 3D and 2D plane cases. They are common to all laws of behavior. Each of them meets the following criteria:

an accumulated plastic deformation, \(p\), of 4 to 5% over the entire path,

a 1% increase in \(p\) during a portion of the trip,

This calibration was carried out on law VMIS_ISOT_LINE, then carried over to the other laws.

The proposed loading causes each component of the deformation tensor to vary in a decoupled manner by successive step. A cyclic load-discharge path is proposed by covering the states of traction and compression as well as an inversion of the signs of shear in order to test a wide range of values.

Schematically, it follows a course over 8 segments \([O-A-B-C-O-C’-B’-A’-O]\) where the second part of the path [O-C”-B”-A”-O] is symmetric with respect to the origin of the first \([O-A-B-C-O]\).

1.3.2. Application of requests#

We come back to the study of a material point (using the macro-command SIMU_POINT_MAT) by soliciting an element in a homogeneous manner by imposing:

in 3D, the 6 components of the deformation tensor:

in 2D the three components of the tensor:

For a more general description, the imposed deformation tensor will be decomposed into a hydrostatic and deviatoric part on shear bases:

in 2D,

In 3D

1.3.3. Description of the imposed deformation path in 2D#

The path applied is described in the table below, the deformation values are calibrated with respect to the elastic modulus:

Time |

1 |

2 |

3 |

3 |

3 |

4 |

5 |

6 |

7 |

8 |

Charging point |

\(A\) |

|

|

|

|

|

|

|

||

\({\varepsilon }_{\mathit{xx}}\mathrm{\times }E\) |

675 |

1350 |

1350 |

1350 |

0 |

-1350 |

-1350 |

-675 |

0 |

|

\({\varepsilon }_{\mathit{yy}}\mathrm{\times }E\) |

675 |

450 |

450 |

1350 |

1350 |

0 |

-1350 |

-450 |

-675 |

0 |

\({\varepsilon }_{\mathit{xy}}\mathrm{\times }E\mathrm{/}(1+\nu )\) |

450 |

180 |

180 |

0 |

0 |

0 |

-180 |

-450 |

0 |

|

\(P\) |

675 |

900 |

900 |

1350 |

-1350 |

-900 |

-675 |

0 |

||

\(D\) |

0 |

0 |

0 |

450 |

450 |

0 |

0 |

0 |

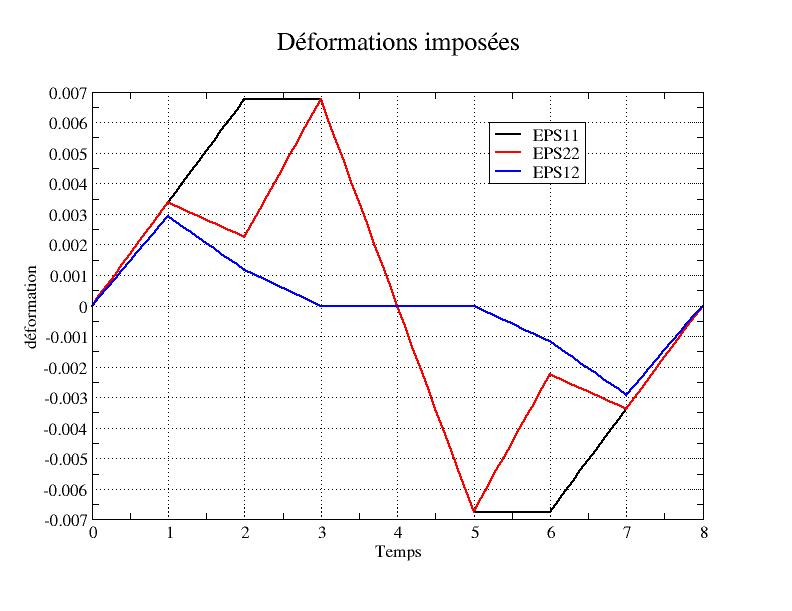

This path is illustrated by the following graph:

1.3.4. Description of the imposed deformation path in 3d#

The path applied is described in the table below, the deformation values applied are calibrated with respect to the elastic modulus:

Segment number |

1 |

2 |

2 |

3 |

3 |

3 |

4 |

5 |

6 |

7 |

8 |

Segment |

\(0-A\) |

|

|

|

|

|

|

|

|||

\({\varepsilon }_{\mathit{xx}}\mathrm{\times }E\) |

787.5 |

1050 |

1050 |

350 |

350 |

0 |

-350 |

-1050 |

-787.5 |

0 |

|

\({\varepsilon }_{\mathit{yy}}\mathrm{\times }E\) |

525.0 |

-175 |

-175 |

-350 |

-350 |

175 |

525 |

0 |

|||

\({\varepsilon }_{\mathit{zz}}\mathrm{\times }E\) |

262.5 |

700 |

700 |

-525 |

-525 |

525 |

-700 |

-262.5 |

0 |

||

\({\varepsilon }_{\mathit{xy}}\mathrm{\times }E\mathrm{/}(1+\nu )\) |

700 |

350 |

350 |

1050 |

1050 |

-1050 |

-350 |

-700 |

0 |

||

\({\varepsilon }_{\mathit{xz}}\mathrm{\times }E\mathrm{/}(1+\nu )\) |

-350 |

350 |

350 |

700 |

700 |

0 |

-700 |

700 |

0 |

||

\({\varepsilon }_{\mathit{yz}}\mathrm{\times }E\mathrm{/}(1+\nu )\) |

0 |

700 |

-350 |

-350 |

0 |

350 |

-700 |

0 |

0 |

||

\(P\) |

525 |

525 |

525 |

-175 |

-175 |

-525 |

-525 |

0 |

|||

\(\mathrm{d1}\) |

262.5 |

525 |

525 |

525 |

0 |

-525 |

-525 |

-262.5 |

0 |

||

\(\mathrm{d2}\) |

262.5 |

-175 |

-175 |

350 |

350 |

0 |

-350 |

175 |

-262.5 |

0 |

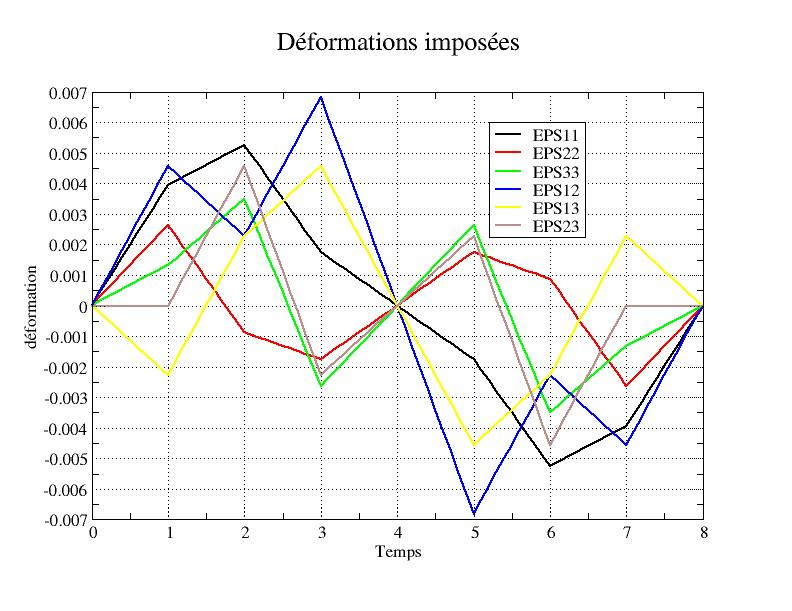

This path is illustrated by the following graph:

1.4. Initial conditions#

Zero stresses and deformations.