3. Modeling A#

Modeling in plane deformations.

3.1. Characteristics of modeling#

The modeling of ductile rupture is carried out with modeling PLAN_INTERFACE and law CZM_TRA_MIX. The volume elements are modelled in plane deformations D_ PLAN.

3.2. Characteristics of the mesh#

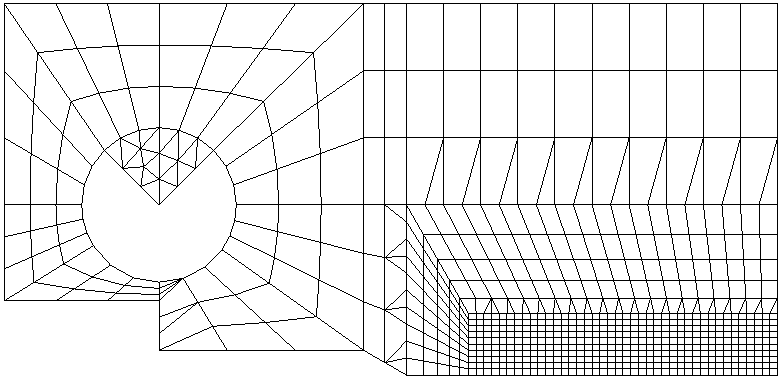

The input mesh is linear. It is transformed into a quadratic mesh by LINE_QUAD in CREA_MAILLAGE.

After the transformation, its characteristics are as follows:

Number of knots: 2357

Number of elements for test piece \(\mathrm{CT}\): 663 QUAD8 and 42 TRIA6

Number of elements for the pin: 20 TRIA6.

Number of interface elements: 40 QUAD8.

Figure 4: 2D CT specimen mesh.

3.3. Tested sizes and results#

Non-regression test: Traction force (resultant \(\mathit{DY}\)) on the pin as a function of the \(\mathit{DY}\) displacement of the pin.

Size tested |

Reference Type |

Code_Aster |

Tolerance ( \(\text{\%}\) )) ** |

Force for a move of \(\mathrm{0,5}\mathit{mm}\) |

“NON_REGRESSION” |

4269.54 |

0.10 |

Force for a move of \(1\mathit{mm}\) |

“NON_REGRESSION” |

4767.59 |

0.10 |

Force for a move of \(\mathrm{1,5}\mathit{mm}\) |

“NON_REGRESSION” |

5109.77 |

0.10 |

Force for a move of \(2\mathit{mm}\) |

“NON_REGRESSION” |

5383.76 |

0.10 |