1. Reference problem#

1.1. Geometry#

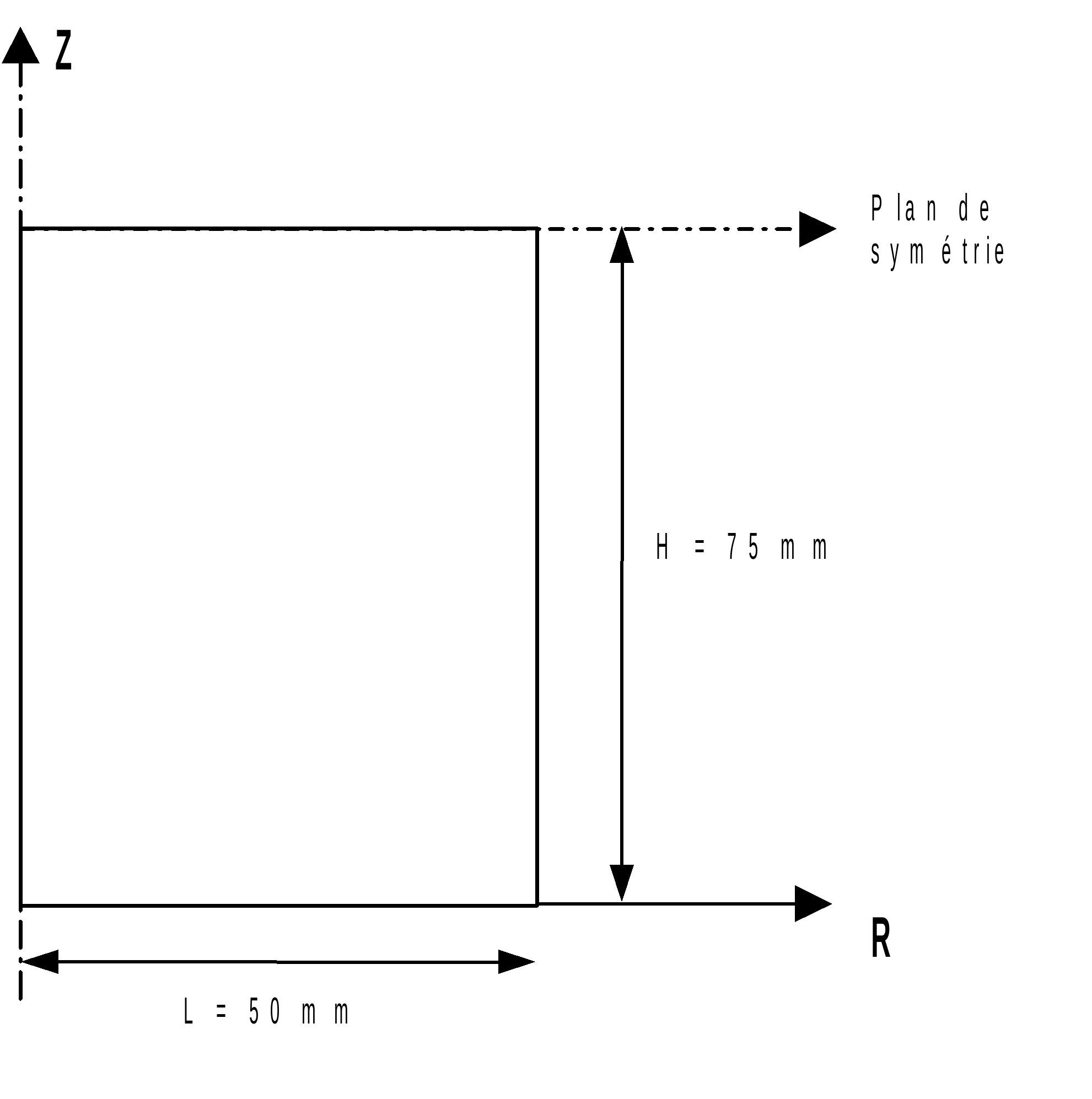

Cylindrical bar:

Overall height: \(\mathrm{2H}=150\mathrm{mm}\)

Diameter: \(\mathrm{2L}=\mathrm{100mm}\)

1.2. Material properties#

The bar is made of 16 MND5 steel. The thermal properties (conductivity and enthalpy of the material) vary with temperature and are given in [bib1].

Coefficient for metallurgy:

TRC « standard »

\(\mathrm{AR3}=830°C\), \(\mathrm{alpha}=-0.0249\)

\(\mathrm{MS0}=415°C\), \(\mathrm{AC1}=724°C\), \(\mathrm{AC3}=846°C\)

\({\tau }_{1}=0.034\), \({\tau }_{3}=0.034\)

Microhardness of the various metallurgical phases:

for ferrite \(d=184.\mathrm{HV}\)

For perlite \(d=184.\mathrm{HV}\)

For the bainite \(d=309.\mathrm{HV}\)

for martensite \(d=450.\mathrm{HV}\)

for austenite \(d=100.\mathrm{HV}\)

1.3. Boundary conditions and loads#

Coefficient of heat exchange with the outside for 14 sec. (before tempering) based on temperature measurements by thermocouples:

Time \((s)\) |

|

13 |

|

\({T}_{\infty }=25°C\)

Surface heat flow density as a function of temperature \(T\) on the borders (during tempering) based on temperature measurements:

\(T(°C)\) |

250 |

||||||||

Flow \((\mathrm{W.m}-2)\) |

|

-0.03 E+06 |

-0.08 E+06 |

-0.08 E+06 |

-0.71 E+06 |

-1.51 E+06 |

-1.51 E+06 |

-1.99 E+06 |

-1.99 E+06 |

\(T(°C)\) |

||||||

Stream \((\mathrm{W.m}-2)\) |

-2.53 E+06 |

-3.34 E+06 |

-3.78 E+06 |

-6. E+06 |

-7. E+06 |

-7.9 E+06 |

1.4. Initial conditions#

\(T(r,z)=906°\mathrm{C.}\)

Bar entirely austenitized in the initial state i.e. \(\mathrm{Zf}(r,z)=0.\), \(\mathrm{Zp}(r,z)=0.\), \(\mathrm{Zb}(r,z)=0.\) and \(\mathrm{Zm}(r,z)=0.\)