1. Reference problem#

1.1. Geometry#

The geometry studied is a parallelepipedic plate 200 mm long, 60 mm wide and 7 mm thick.

Specimen thickness |

Width of The test tube |

Length of The test tube |

\(7\mathrm{mm}\) |

|

|

1.2. Material properties#

The material under consideration is a forged austenitic stainless steel of type 316L (Z2 CND17 -12).

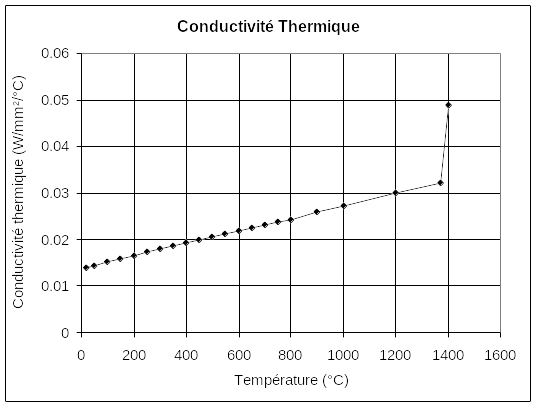

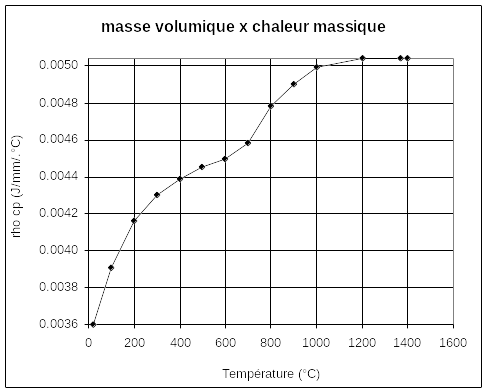

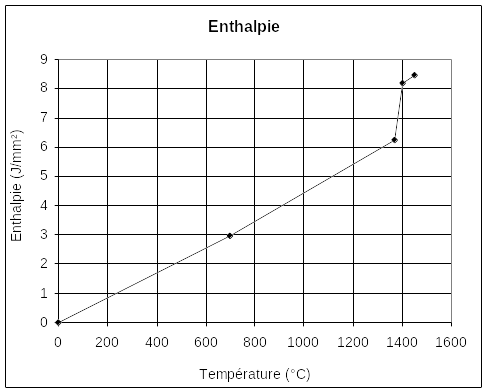

For non-linear thermal modeling, thermal conductivity and the product (density, density, heat capacity \(\rho c\)) vary as a function of temperature. Their values are given in the table below:

\(T\) Temperature (\(°C\)) |

\(\lambda\) Thermal conductivity (\(W/(\mathrm{mm}°C)\)) |

\(\rho c\) (\(J/{\mathrm{mm}}^{3}°C\)) |

\(\beta\) Enthalpy (\(J/{\mathrm{mm}}^{3}\)) |

20 |

14.0 E-3 |

36.00 E-4 |

0.0 |

50 |

14.4 E-3 |

||

100 |

15.2 E-3 |

39.05 E-4 |

|

150 |

15.8 E-3 |

||

200 |

16.6 E-3 |

41.63 E-4 |

|

250 |

17.3 E-3 |

||

300 |

17.9 E-3 |

43.00 E-4 |

|

350 |

18.6 E-3 |

||

400 |

19.2 E-3 |

43.90 E-4 |

|

450 |

19.9 E-3 |

||

500 |

20.6 E-3 |

44.50 E-4 |

|

550 |

21.2-3 |

||

600 |

21.8 E-3 |

44.95 E-4 |

|

650 |

22.4 E-3 |

||

700 |

23.1 E-3 |

45.80 E-4 |

2.979 |

750 |

23.7 E-3 |

||

800 |

24.3 E-3 |

47.80 E-4 |

|

900 |

26.0 E-3 |

49.00 E-4 |

|

1000 |

27.3 E-3 |

49.90 E-4 |

|

1200 |

29.9 E-3 |

50.40 E-4 |

|

1370 |

32.2 E-3 |

50.40 E-4 |

6.232 |

1400 |

48.9 E-3 |

50.40 E-4 |

8.184 |

1450 |

8.444 |

1.3. Boundary conditions#

The welding parameters are shown in the table below:

\(I\) (Intensity) |

\(U\) (Voltage) |

\(V\) (Workpiece speed) |

Electrode diameter |

\(\mathrm{200A}\) |

|

|

|

The upper surface of the plate is subjected to the action of a torch. This torch is placed in the center of the plate, \(15\mathrm{mm}\) from the edge, and moves parallel to its length at a constant speed (\(\mathrm{14cm}/\mathrm{min}\)) up to \(\mathrm{85.5mm}\) from the edge corresponding to the flashlight’s off position.

1.4. Initial conditions#

None.