3. C modeling#

3.1. Characteristics of modeling#

Tested behavior: gursonTvergaardNeedlemanplasticflow_numericaljacobian.mfront

Elasto-plastic law with Gurson damage (model GTN in the literature).

Ref: « Analysis of the cup cone fracture in a round tensile bar ».

V.Tvergaard, A.Needleman, Acat Metallurgica 32 (1984) 157-169

the criterion is of the shape (f is the porosity)

\(F(\sigma ,f)={(\frac{{\sigma }_{\mathit{eq}}}{{\sigma }_{0}})}^{2}+2{q}_{1}f\mathrm{cosh}(\frac{3}{2}{q}_{2}\frac{{\sigma }_{h}}{{\sigma }_{0}})-1-{({q}_{1}f)}^{2}\le 0\)

Isotope work hardening is modified as follows (

\(R(p)=\mathit{R0}+{Q}_{1}(1–{e}^{-{b}_{1}p})+{Q}_{2}(1–{e}^{-{b}_{2}p})\)

Modeling: material point subject to imposed deformations:

\({\epsilon }_{\mathit{xx}}=\mathrm{0,02}t\), \({\epsilon }_{\mathit{yy}}=\mathrm{0,1}t\) \({\epsilon }_{\mathit{zz}}=0\)

Material properties:

Young |

200000 |

Fish |

0.3 |

R0 |

500 |

Q1 |

1e9 |

b1 |

1-e-6 |

Q2 |

0 |

b2 |

0 |

f0 |

1-e-3 |

fc |

1-e-2 |

delta |

2 |

beta |

0 |

Cp |

|

app |

1 e-5 |

q1 |

1.5 |

q2 |

1 |

3.2. Tested sizes and results#

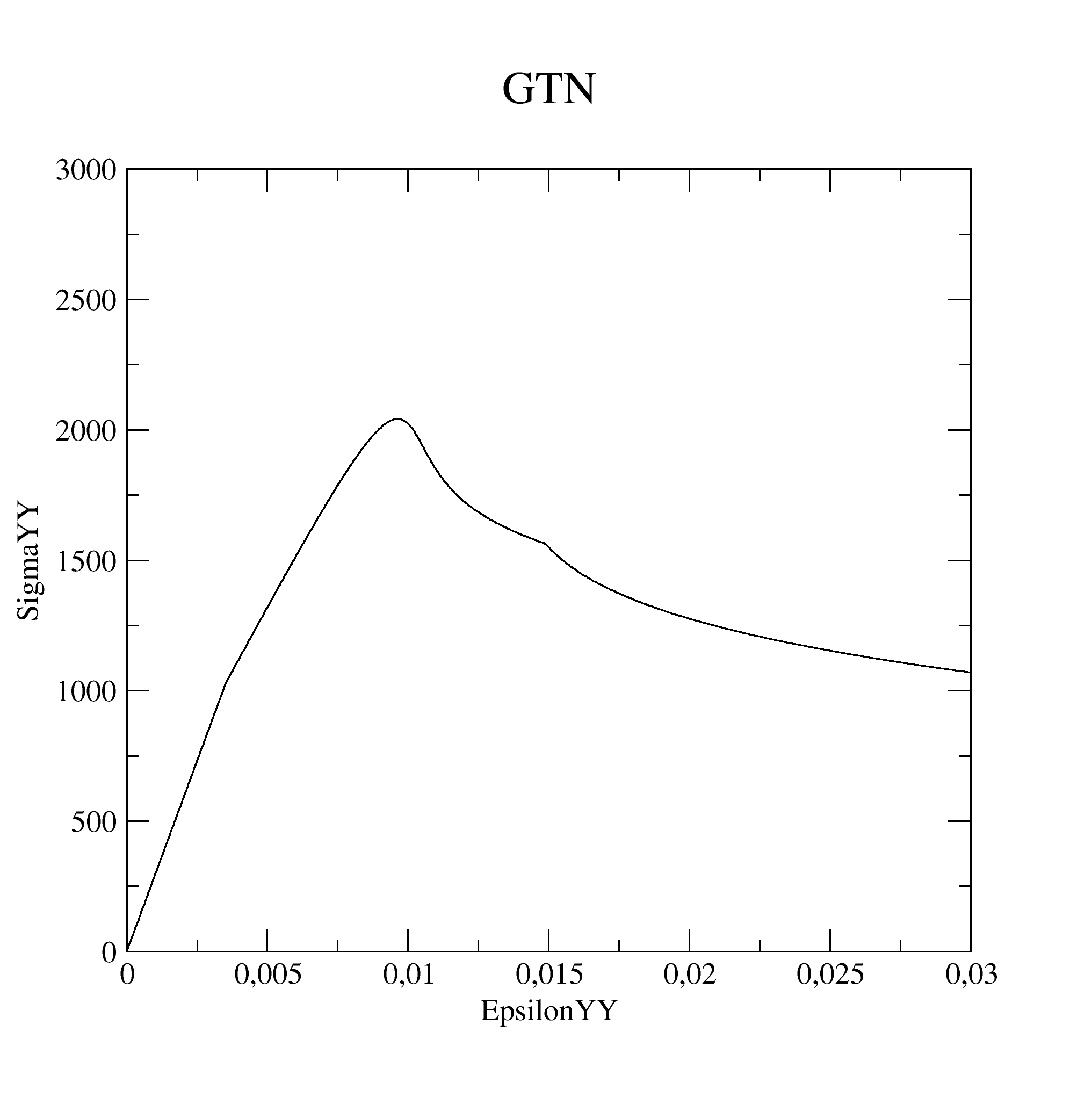

Response curve \({\sigma }_{\mathit{yy}}=f({\epsilon }_{\mathit{yy}})\) is:

The tests are non-regression.

Identification |

Instants |

Reference |

Tolerance |

\({\sigma }_{\mathit{xx}}\) |

0.3 |

910.12 |

|

\({\sigma }_{\mathit{yy}}\) |

0.3 |

1069.37 |

|

\({\sigma }_{\mathit{zz}}\) |

0.3 |

870.308 |

|