1. Reference problem#

1.1. Geometry#

It is a material point, representative of a state of homogeneous stresses and deformations.

1.2. Material properties#

1.2.1. Umat data#

The coefficients of Umat behavior are (cf. [U4.43.01]):

\(\mathrm{C1}=\lambda =\frac{E\nu }{(1+\nu )(1-2\nu )}\)

\(\mathrm{C2}=\mu =\frac{E}{2(1+\nu )}\)

\(\mathrm{C3}=\tilde{\lambda }=\frac{\lambda }{20}\)

\(\mathrm{C4}=\tilde{\mu }=\frac{\mu }{20}\)

\(\mathrm{C5}=\tilde{\nu }=0\)

We will use: DEFI_MATERIAU/UMAT =_F (LISTE_COEF =( C1, C2, C3, C4, C5)),

1.3. Boundary conditions and loads#

The load is the same as in tests COMP001, see [V6.07.101].

1.3.1. Characteristics of loading paths#

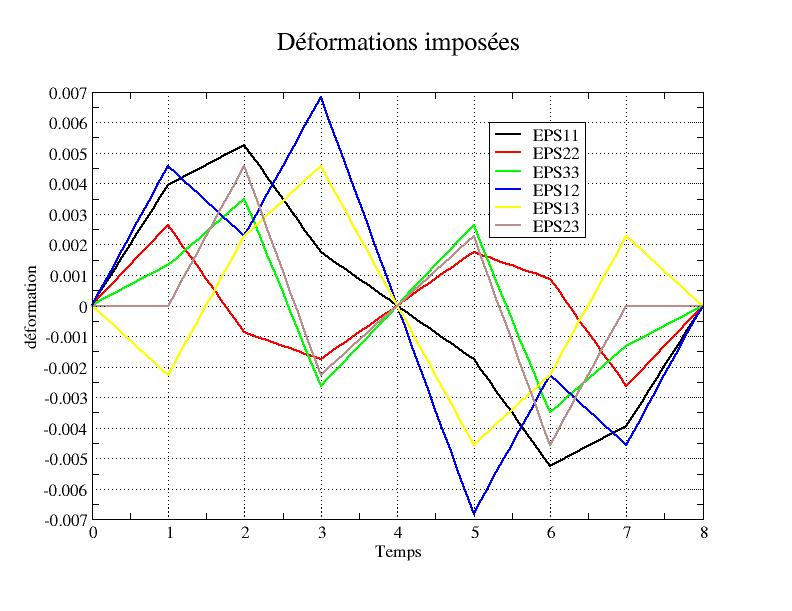

The proposed loading causes each component of the deformation tensor to vary in a decoupled manner by successive step. A cyclic load-discharge path is proposed by covering the states of traction and compression as well as an inversion of the signs of shear in order to test a wide range of values.

Schematically, it follows a course on 8 segments \([O-A-B-C-O-C’-B’-A’-O]\) where the second part of the path \([O-C’-B’-A’-O]\) is symmetric with respect to the origin of the first \([O-A-B-C-O]\).

1.3.2. Application of requests#

We come back to the study of a material point (using the macro-command SIMU_POINT_MAT [U4.51.12]) by stressing an element in a homogeneous manner by imposing in \(\mathrm{3D}\), the 6 components of the deformation tensor:

\(\stackrel{ˉ}{\varepsilon }=\left[\begin{array}{ccc}{\varepsilon }_{\mathrm{xx}}& {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{xz}}\\ {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{yy}}& {\varepsilon }_{\mathrm{yz}}\\ {\varepsilon }_{\mathrm{xz}}& {\varepsilon }_{\mathrm{yz}}& {\varepsilon }_{\mathrm{zz}}\end{array}\right]\)

For a more general description, the imposed deformation tensor will be decomposed into a hydrostatic and deviatoric part on shear bases:

\(\stackrel{ˉ}{\varepsilon }=\left[\begin{array}{ccc}{\varepsilon }_{\mathrm{xx}}& {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{xz}}\\ {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{yy}}& {\varepsilon }_{\mathrm{yz}}\\ {\varepsilon }_{\mathrm{xz}}& {\varepsilon }_{\mathrm{yz}}& {\varepsilon }_{\mathrm{zz}}\end{array}\right]=p\left[\begin{array}{ccc}1& 0& 0\\ 0& 1& 0\\ 0& 0& 1\end{array}\right]+{d}_{1}\left[\begin{array}{ccc}1& 0& 0\\ 0& -1& 0\\ 0& 0& 0\end{array}\right]+{d}_{2}\left[\begin{array}{ccc}0& 0& 0\\ 0& 1& 0\\ 0& 0& -1\end{array}\right]+\left[\begin{array}{ccc}0& {\varepsilon }_{\mathrm{xy}}& {\varepsilon }_{\mathrm{xz}}\\ {\varepsilon }_{\mathrm{xy}}& 0& {\varepsilon }_{\mathrm{yz}}\\ {\varepsilon }_{\mathrm{xz}}& {\varepsilon }_{\mathrm{yz}}& 0\end{array}\right]\) in 3D.

1.3.3. Description of the imposed deformation path in 3D#

The path applied is described in the table below, the deformation values applied are calibrated with respect to the elastic modulus:

Segment number |

1 |

2 |

2 |

3 |

3 |

3 |

4 |

5 |

6 |

7 |

8 |

Segment |

\(0-A\) |

|

|

|

|

|

|

|

|||

\({\varepsilon }_{\mathrm{xx}}\ast E\) |

787.5 |

1050 |

1050 |

350 |

350 |

0 |

-350 |

-1050 |

-787.5 |

0 |

|

\({\varepsilon }_{\mathrm{yy}}\ast E\) |

525.0 |

-175 |

-175 |

-350 |

-350 |

175 |

525 |

0 |

|||

\({\varepsilon }_{\mathrm{zz}}\ast E\) |

262.5 |

700 |

700 |

-525 |

-525 |

525 |

-700 |

-262.5 |

0 |

||

\({\varepsilon }_{\mathrm{xy}}\ast E/(1+\nu )\) |

700 |

350 |

350 |

1050 |

1050 |

-1050 |

-350 |

-700 |

0 |

||

\({\varepsilon }_{\mathrm{xz}}\ast E/(1+\nu )\) |

-350 |

350 |

350 |

700 |

700 |

0 |

-700 |

700 |

0 |

||

\({\varepsilon }_{\mathrm{yz}}\ast E/(1+\nu )\) |

0 |

700 |

-350 |

-350 |

0 |

350 |

-700 |

0 |

0 |

||

\(P\) |

525 |

525 |

525 |

-175 |

-175 |

-525 |

-525 |

0 |

|||

\(\mathrm{d1}\) |

262.5 |

525 |

525 |

525 |

0 |

-525 |

-525 |

-262.5 |

0 |

||

\(\mathrm{d2}\) |

262.5 |

-175 |

-175 |

350 |

350 |

0 |

-350 |

175 |

-262.5 |

0 |

This path is illustrated by the following graph:

1.4. Initial conditions#

Zero stresses and deformations.