1. Reference problem#

1.1. Geometry#

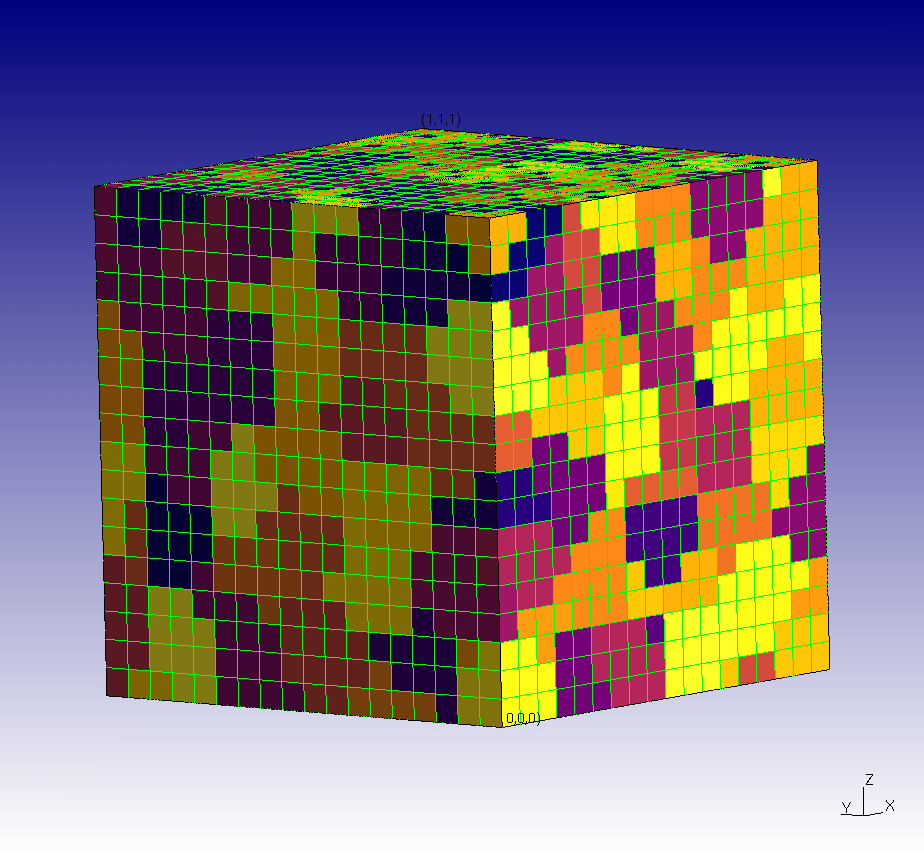

The aggregate is represented by a regulated hexahedral mesh occupying a volume with side 1.

It comprises 300 grains, defined by the belonging of each of the cells to a particular group of elements centered around a germ positioned randomly in the cube.

1.2. Material properties#

Elastic behavior with: |

Young’s module: |

Poisson’s ratio: |

|

Behavior mono-crystalline, with BCC24 sliding system.

The behavior of the single crystal is defined by:

Type of flow: MONO_VISC1 whose parameters are:

Isotropic work hardening type: MONO_ISOT1 ** whose parameters are:

(interaction between sliding systems)

No kinematic work hardening: MONO_CINE1

1.3. Boundary conditions and loads#

Face \(z\mathrm{=}0\) |

: |

Face \(y\mathrm{=}0\) |

: |

Face \(x\mathrm{=}0\) |

: |

Face \(z\mathrm{=}1\) |

: |

The load

is increasing linearly from 0 for \(t\mathrm{=}0\) to \(0.1\) for \(t\mathrm{=}\mathrm{100s}\).

To reduce the calculation time, this one is carried up to \(t\mathrm{=}\mathrm{1.8s}\), i.e. an imposed deformation of \(\text{0.18\%}\), in 3 increments.