4. Scope of use#

The scope of application of the macro-command is specified in this paragraph.

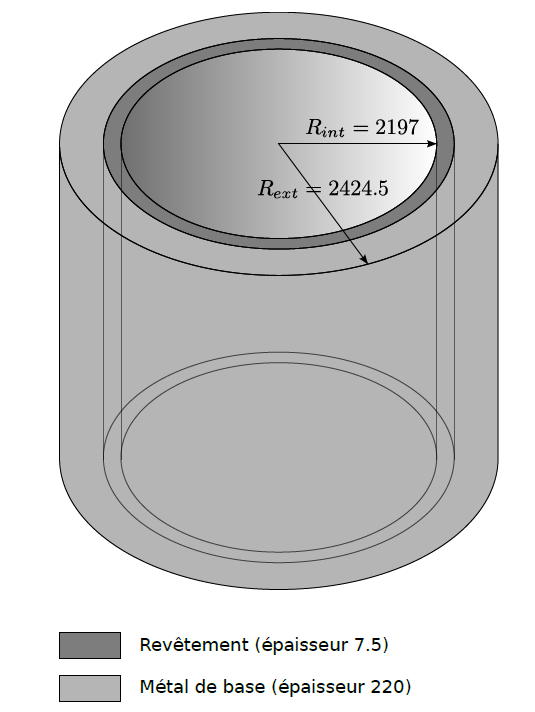

On the one hand, the components concerned are tanks made of low alloy steel 16 MND5 (base metal), coated on the inner surface with a coating of 309L and 308L austenitic stainless steel, as illustrated on the.

Figure 4-1: Example of a 3D geometry of the core zone of a 1300 MWe tank lined on the inner surface (units: mm).

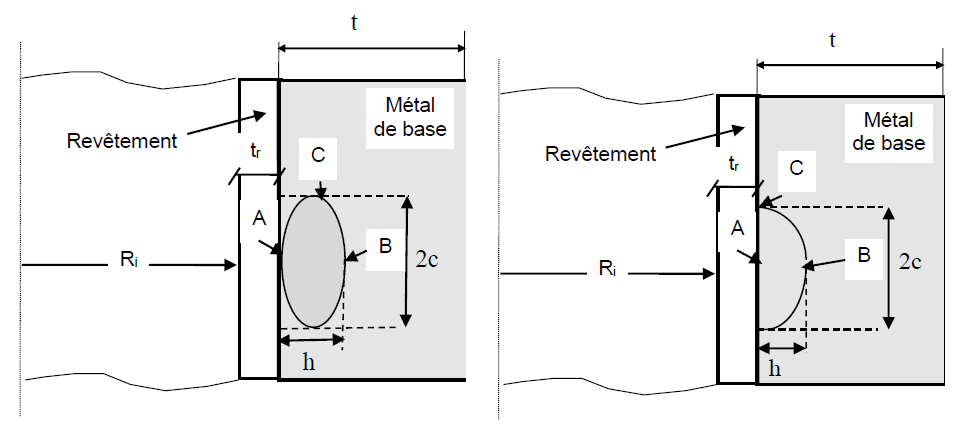

On the other hand, the macro-command allows the analysis of the harmfulness of the following defects:

Defects under elliptical or semi-elliptical coating (DSRs) (see Figure 4-2 for the illustration from RSE -M),

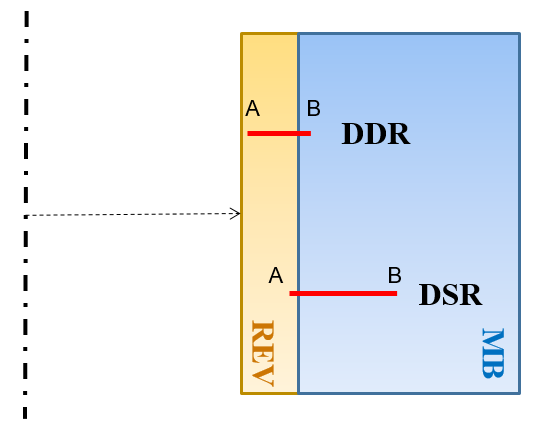

Defects in the elliptical or semi-elliptical (DDRs) coating (see Figure 4-3 for a schematization of a DDR and a DSR in 2D).

These two defects each have a point located on the Stainless Steel coating side and a point located in the Ferritic Steel base metal. The macro control focuses on the risk of fragile rupture for the point of the defect located on the base metal side, i.e. the point on the crack front named B in figures and.

Figure 4-2: geometry of the defect under elliptical or semi-elliptical coating. The margin factor is calculated at point B, in the base metal

Figure 4-3: Diagram of a DDR (upper red segment) and a DSR (lower red segment) in 2D. The margin factor is calculated at point B, in the base metal