1. Physical framework and concepts of the LETK model#

The objective of this paragraph is not to describe in an exhaustive way the approach taken by [1] and [2] to lead to the development of the LETK model. The aim is to come back to some points essential to the understanding of paragraphs § 2 and § 3. We invite the reader to refer to [1] and [2] for more details. The concepts presented in this paragraph were retained by [3] in developing the LKR model.

The model presented by [2] is an elasto (visco) plastic model with two mechanisms. The first mechanism, elastoplastic, seeks to describe the instantaneous deviatoric behavior of geomaterials. The second mechanism, viscoplastic, reflects the effect of time on deviatoric behavior.

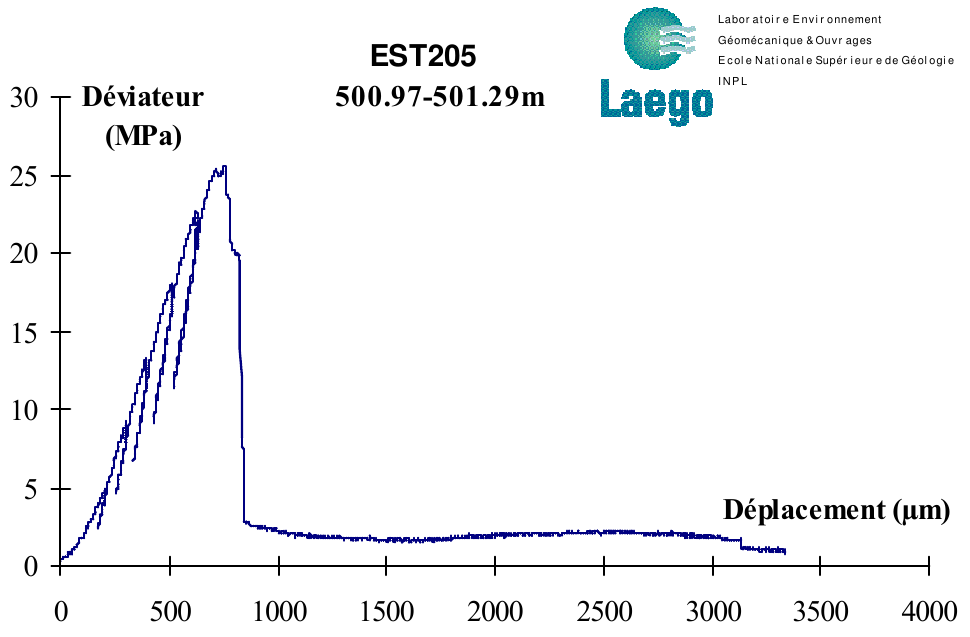

Instantaneous deviatoric behavior is characterized by simple/triaxial compression and extension tests (among others). The conceptual framework adopted for the development of the elastoplastic mechanism is mainly based on the analysis of the behavior under triaxial compression. The response of geomaterials to this type of stress is divided into two phases (see Figure). For relatively low deformations, the strength of a sample increases with its axial deformation. This phase, referred to as pre-peak, ends when the material reaches its maximum strength. Beyond this peak, the resistance decreases until it reaches a residual value. The evolution of a material between its peak and residual resistances is called post-peak. pre-pic and*post-pic* behaviors are detailed in paragraph § 1.1.

The effect of time on deviatoric behavior is characterized by tests of creep, relaxation, or triaxial compression at various loading rates. The conceptual framework adopted for the development of the viscoplastic mechanism is mainly based on the analysis of the behavior during a creep test. This point is detailed in paragraph § 1.2.

Figure 1.1: Simple compression test on Cox argillite [4].

1.1. Elastoplastic mechanism#

The elastoplastic mechanism seeks to reproduce the following phenomena [1]:

the elastic behavior is non-linear for low deformations;

the maximum resistance depends on the level of confinement;

post-peak softening is governed by the gradual loss of cohesion and by the evolution of the angle of dilatance;

the residual state, or critical state, is characterized by zero cohesion, zero dilatance and purely rubbing behavior.

1.1.1. Pre-peak behavior#

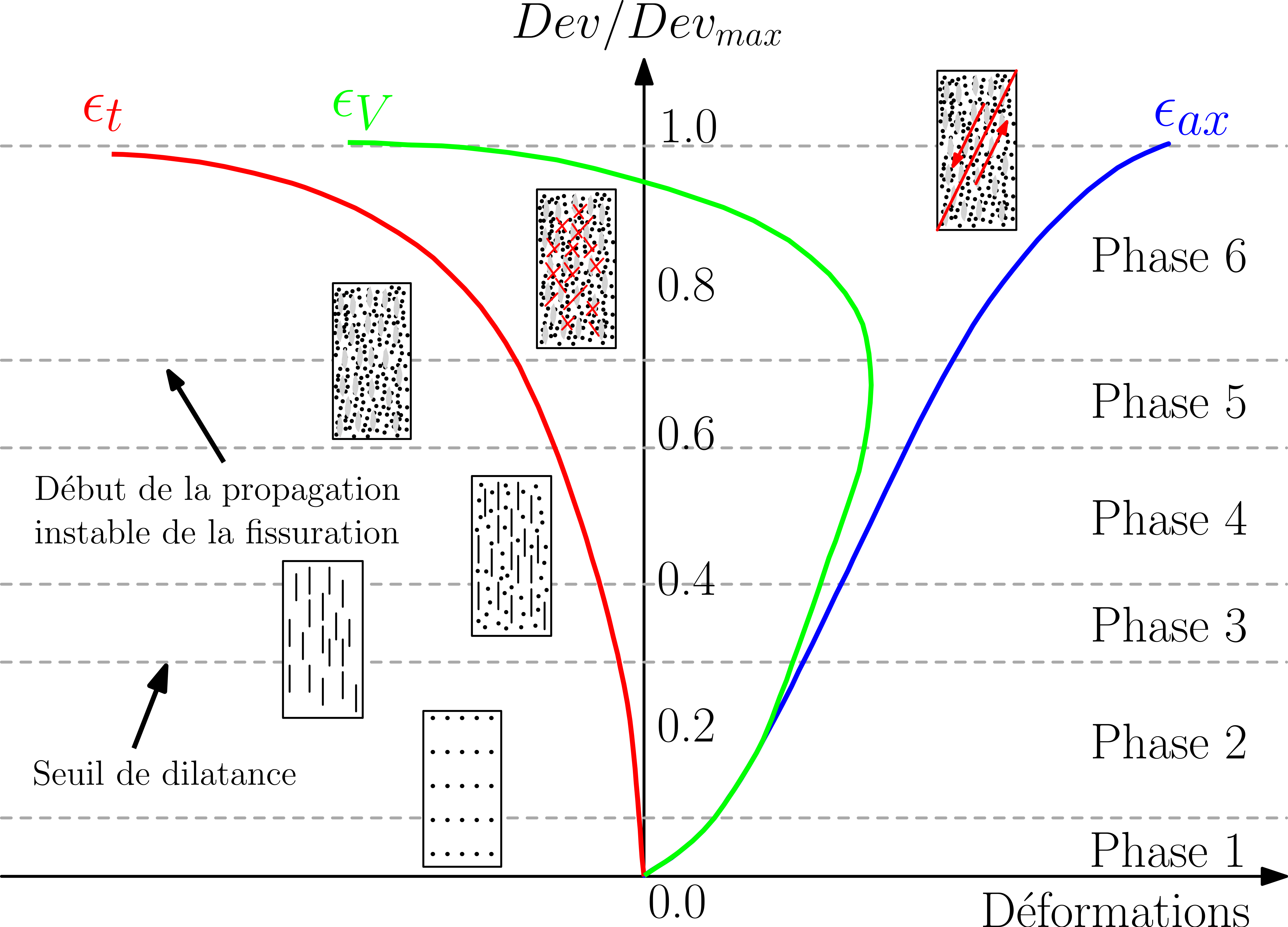

Pre-peak behavior can be broken down into several phases. For example, [2] and [5] distinguish six (see Figure):

This phase, called tightening, concerns low stress levels. It is accompanied by a contraction of the sample and reflects the initial closure of pre-existing cracks within the material. This phase is considerably reduced, or even non-existent, when confinement pressure is applied to the sample.

This phase corresponds to the linear/elastic part of the stress-strain curve and rarely exceeds 40% of the maximum strength. The volume behavior remains contracting but evolves more slowly than during the first phase.

This phase marks the initiation of cracking and expansion. However, the propagation of the cracks created remains stable. The stress level corresponding to this phase is generally between 30% and 60% of the maximum resistance.

For deviators between 50% and 60% of the maximum strength, a significant intensification of cracking is observed. An increase in confinement pressure has a stabilizing effect on the development of these cracks.

The cracks begin to coalesce. This phase corresponds to deviators between 70% and 90% of the maximum resistance.

Phases 3, 4 and 5 are not always the subject of such a distinction. Their characterization and the levels of diverters to which they correspond depend strongly on the confinement pressure applied to the sample. For low lockdowns, cracking will quickly become unstable as early as the third phase. At high lockdown, this transition may be delayed until the end of the fifth phase.

This phase is associated with the unstable development of cracking and a significant increase in expansion up to the maximum strength of the sample.

Figure 1.2: Phases characterizing the mechanical and volume changes of a material during simple or triaxial compression tests (from [5] taken up by [2])

In a simplified way, we will remember three phases:

Phases 1 and 2 may constitute a single domain within which the behavior is elastic. The upper limit of this phase corresponds to the elastic limit of the material.

Phases 3, 4 and 5 can also constitute a single domain that marks a transition in volume behavior (stable/unstable cracking). For low confinements, this transition takes place for low stress levels, close to the initial elastic limit. For high confinement pressures, this transition can take place for stress levels that are very close to the peak of resistance.

Phase 6 is associated with the unstable development of cracking. The upper limit of this phase coincides with the maximum strength of the material.

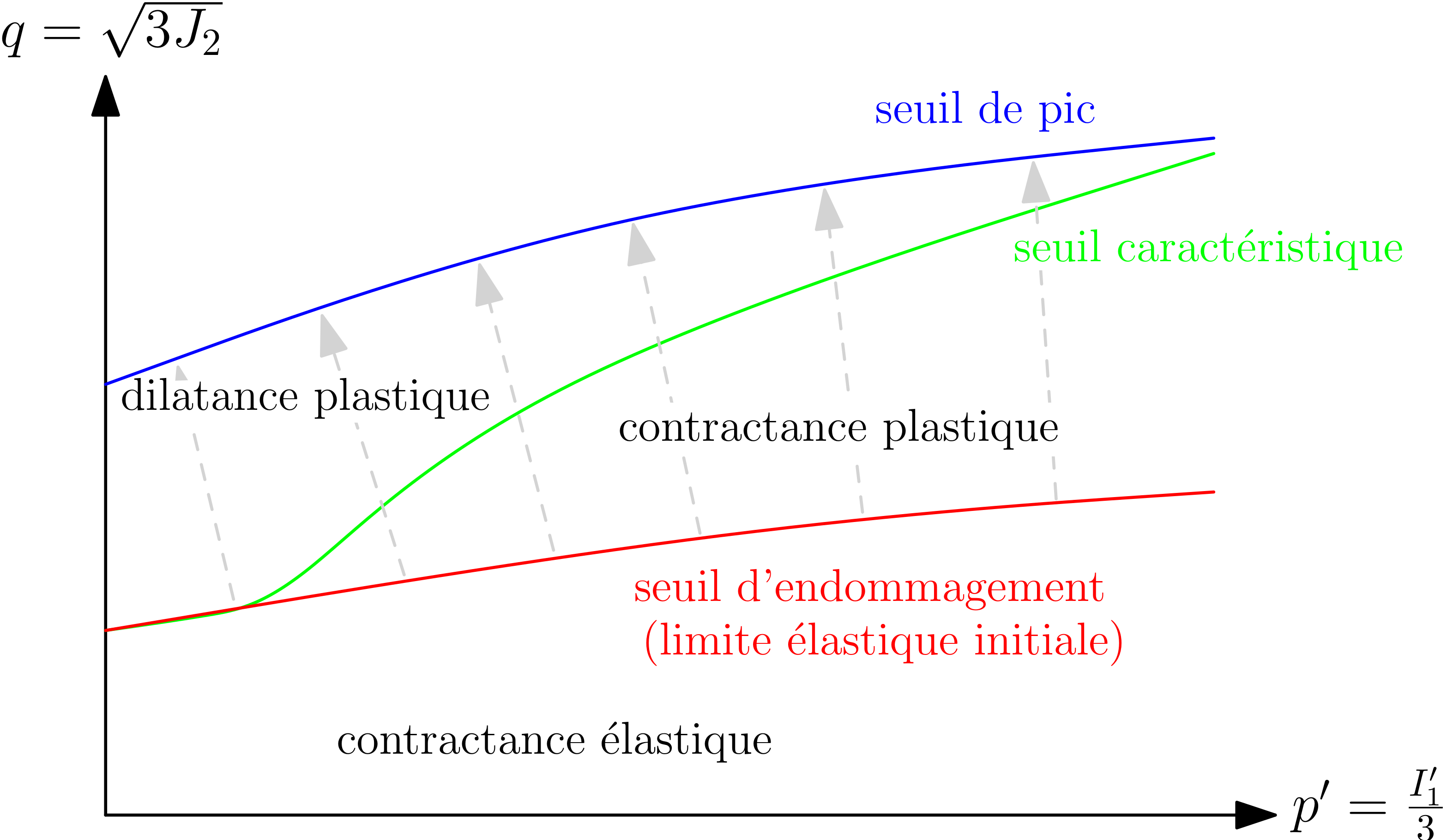

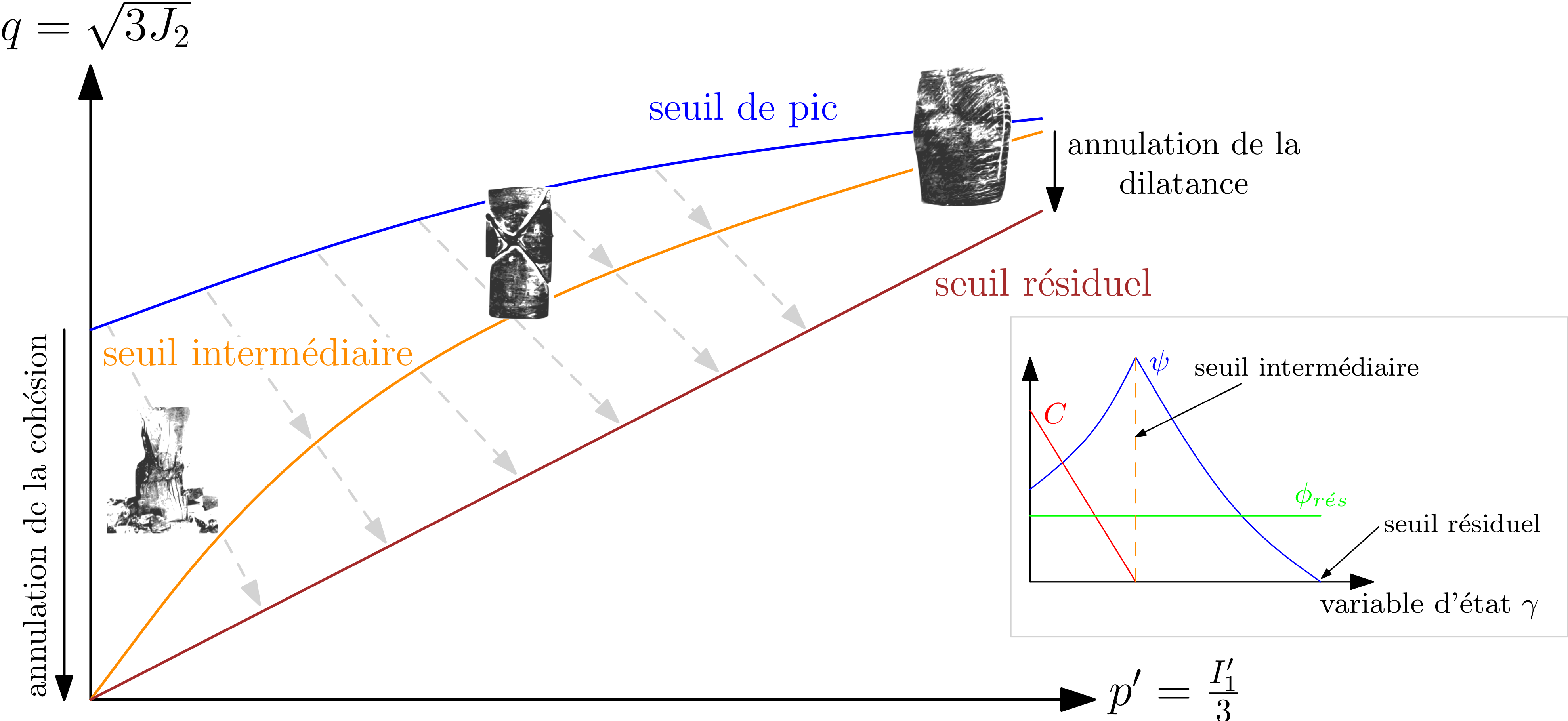

This decomposition into three simplified phases makes it possible to define three thresholds in the constraint space (Figure). The upper limits of domains 1 and 3 characterize mechanical thresholds: initial elastic limit and maximum strength, also called peak resistance. The upper limit of phase 2. marks a transition in volume behavior (contract/dilatance). This transition between contracting and dilating behaviors occurs for states of stress called characteristic states [6] and [7]. The set of characteristic states obtained for triaxial compression tests at various confinement pressures defines the characteristic threshold.

Figure 1.3: Evolution thresholds in the pre-peak phase.

In the framework chosen by [2], pre-peak work hardening therefore results in a dilation of the elastic domain between the thresholds damage (or initial elasticity limit) and peak (or maximum resistance) (Figure).

When the stress state is between the initial elastic limit and the characteristic threshold, the plastic volume behavior is qualified as contracting. When the stress state is between the characteristic threshold and the peak threshold, the plastic volume behavior is qualified as dilating. The characteristic threshold is defined as the union of the initial elastic limit (for low lockdowns) and a threshold called the cleavage limit in reference to the work done by [8] and [9] (higher confinements) (Figure).

1.1.2. Post-peak behavior#

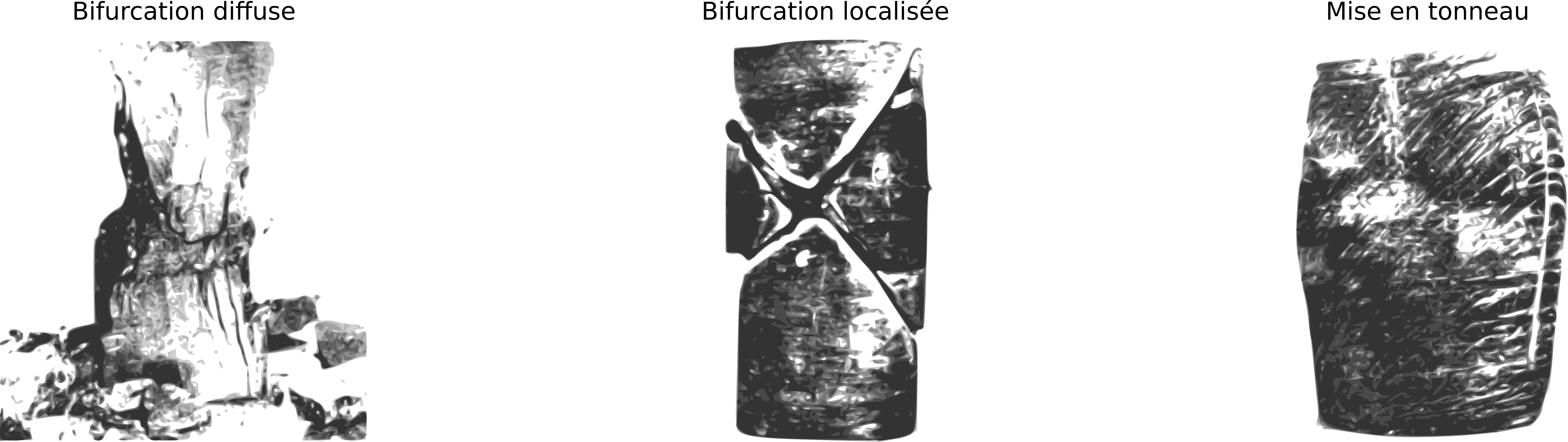

Post-peak behavior characterizes the evolution of the material near and beyond the resistance peak (between its maximum and residual resistances). Most coherent materials show softening behavior after reaching peak strength. This domain reflects a deterioration in the mechanical properties of the material and, in particular, a loss of cohesion. Post-peak behavior is highly dependent on confinement [2]. An increase in confinement pressure tends to stabilize the drop in resistance. However, this stabilization is gradual and is a function of external parameters such as the stress rate, the temperature, the stress path, the interstitial pressure, etc. Several rupture facies, or failure modes [1], are observed as a function of the confinement pressure. It is commonly accepted to distinguish three:

Weak confinement: the sample ruptures by*cleavage, the rupture is fragile and explosive. This mode of rupture is qualified as*diffuse bifurcation* by [10] (Figure);

Intermediate confinement: the formation of one or more shear structures within the sample controls the loss of strength (Figure). As soon as these so-called*induced*structures [:ref:`1 <1>`] are created, the loss of resistance is entirely controlled by the behavior along these discontinuities up to the residual threshold (residual resistance criterion, critical state of the material, purely rubbing behavior, zero cohesion and expansion). This mode of rupture is qualified as*localized bifurcation by [10];

High confinement: behavior becomes ductile. The sample can be significantly deformed without loss of strength and homogeneity. The volume behavior can remain purely contractual. There is*barreling of the sample (Figure).

The work carried out by [1] and [2] made it possible to highlight the existence of an intermediate state between the maximum and residual resistances of a material. This state coincides with a total loss of cohesion and a maximum of expansion, which correspond to the formation of one or more shear surfaces (Figure). All of these intermediate states define a threshold in the constraint space, called intermediate threshold. [1] and [2] assume that the intermediate threshold coincides with the second part of the characteristic threshold introduced in paragraph § 1.1.1. However, these two thresholds should not be confused. The characteristic threshold is a transition threshold in pre-peak volume behavior while the intermediate threshold is a mechanic threshold by which the elastic domain collapses in post-peak regime. The volume behavior in the post-peak phase is always dilating, regardless of the stress state. The evolution of the elasticity domain for post-peak behavior therefore takes place in two stages [2]:

A first transition between peak and intermediate thresholds during which the cohesion of the material will progressively be cancelled out (magnitude \(C\) in the Figure) while the dilatance will increase to reach its maximum on the intermediate threshold (magnitude \(\mathrm{\psi }\) in the Figure).

A second transition between intermediate and residual thresholds during which the dilatance decreases by progressive wear of the lips of the shear structures created at the intermediate threshold (Figure). On the residual threshold, cohesion and dilatance are zero, the behavior is purely rubbing (critical state) (quantity \({\mathrm{\phi }}_{\mathit{rés}}\) in the Figure).

Figure 1.4: The different modes of rupture according to confinement [1]

For low lockdowns, the transition between peak threshold and residual threshold is mainly due to a loss of cohesion. There is rupture by diffuse cleavage or bifurcation (Figure). The expansion is only increasing, no independent shear surface is created. For higher lockdowns, the trend is reversed; the role of dilatance is becoming increasingly important (Figure).

1.2. Figure 1.5: Thresholds of evolution in the post-peak phase. Viscoplastic mechanism#

The effect of time on the behavior of a material is expressed by various phenomena. Examples include:

Consolidation: decrease in volume over time following drainage of the material (hydromechanical phenomenon).

Swelling: increase in volume caused by chemical changes in the structure of the rock.

Creep: delayed deformations under constant loading.

Relaxation: relaxation of stresses with constant deformation.

Aging: degradation of the mechanical properties of rock following a chemical alteration of its constituent minerals.

Healing: physicochemical phenomenon of recrystallization allowing the rock to regain its mechanical properties.

The delayed deviatoric behavior of geomaterials can be characterized by various types of tests:

Triaxial compression tests at different stress rates: it is commonly accepted that the maximum resistance of a material decreases with a decrease in the loading speed [2].

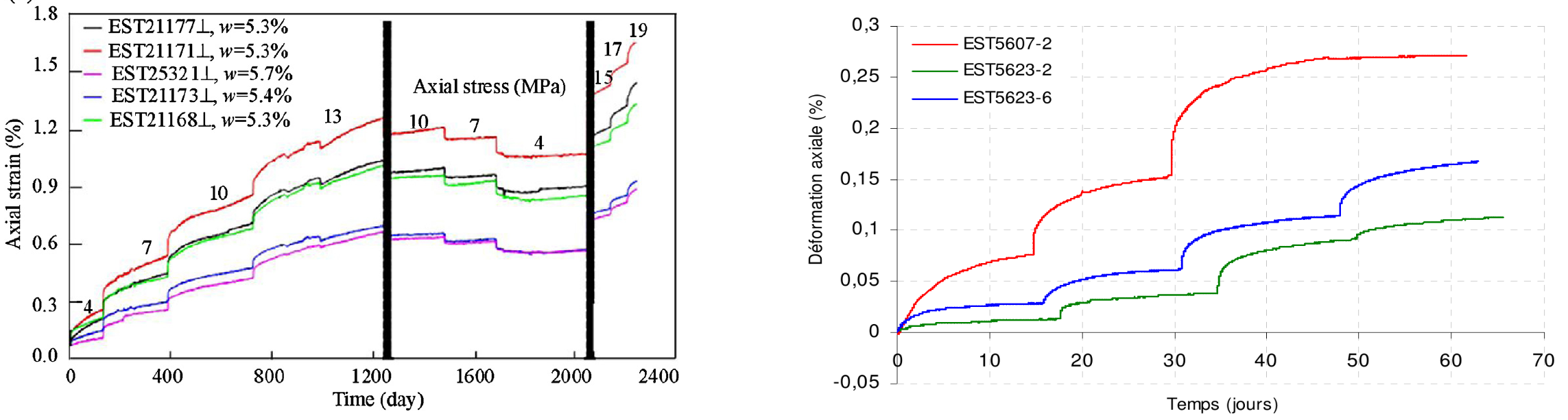

Creep tests (Figure): a diverter is kept constant after an isotropic confinement phase. The evolution of axial deformations as a function of time makes it possible to characterize the speed and the amplitude of the delayed effects. Three distinct regimes are generally demonstrated: a primary creep during which the creep rate only decreases over time; a secondary creep during which the creep rate is constant; a tertiary creep during which the creep rate increases rapidly. The latter regime generally leads to sample breakage.

Relaxation tests: the deformation is kept constant. The drop in stress over time also makes it possible to characterize the speed and magnitude of delayed effects.

Figure 1.6: Results of creep tests carried out on Cox argillite [11] taken up by [12] (on the left), [13] taken up by [2] (on the right).

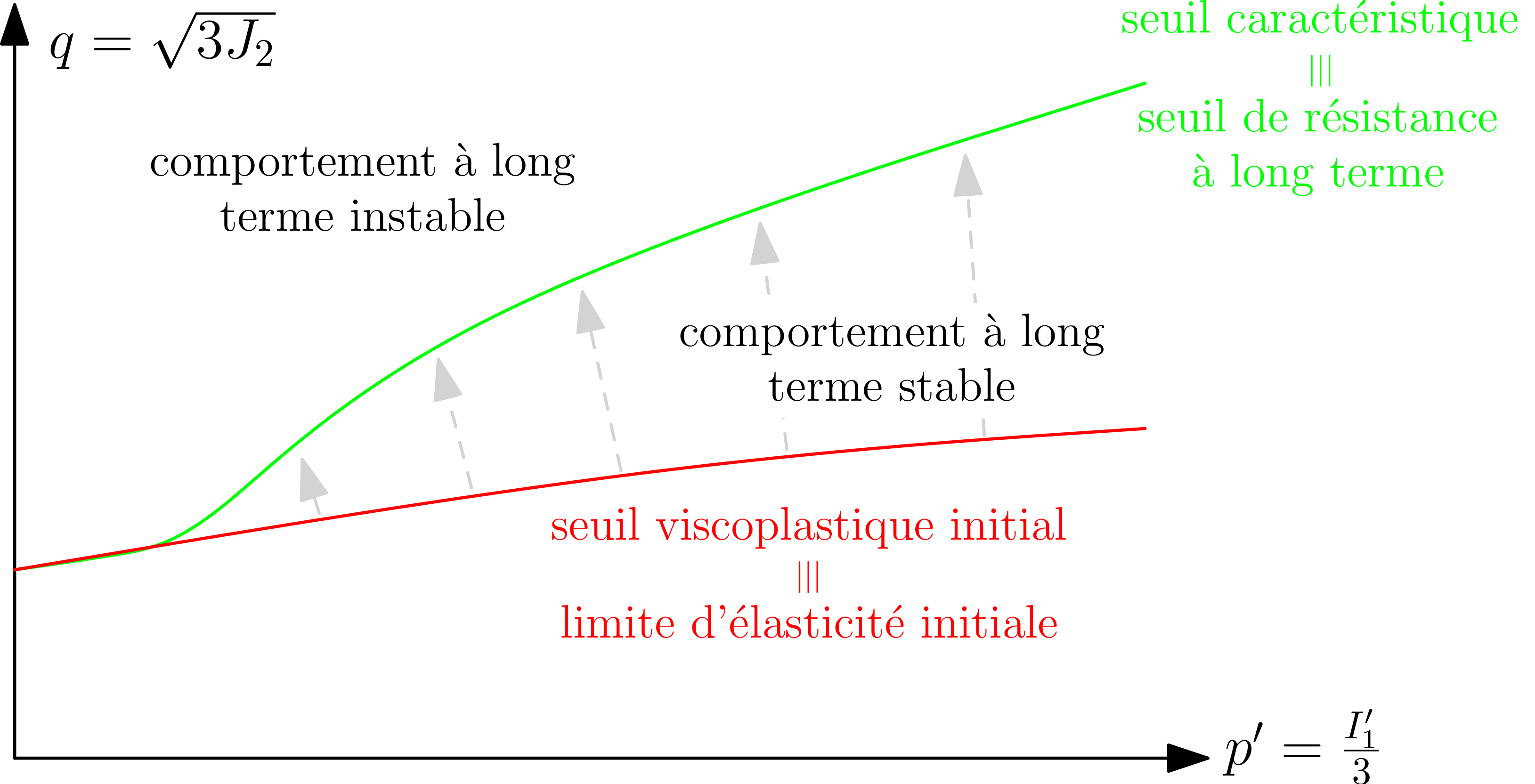

Depending on the level of diverter applied to a sample, the three creep regimes shown above may or may not exist. For low diverter levels, creep stabilizes quickly (primary creep). For higher deviators, long-term behavior evolves in an unstable manner. The transition time between secondary and tertiary creep depends on the level of stress applied and on external parameters such as temperature. An increase in confinement pressure stabilizes behavior in the long term. Identifying stress states corresponding to the transition between stable and unstable long-term behaviors for different confinement pressures makes it possible to define a threshold in the stress space, called the maximum viscoplastic threshold. This threshold is also called the long-term strength threshold by [2] because the level of transition stress between stable and unstable creeps also corresponds to the maximum resistance that can be reached during a triaxial compression test at an infinitely slow loading rate.

Figure 1.7: Evolution thresholds for the viscoplastic mechanism.

The existence of this threshold is not unanimously accepted by the scientific community because its determination remains difficult to define, in particular for materials with slow creep kinetics. However, based on several studies listed by [2], the LETK model uses as a long-term resistance threshold, the threshold for the initiation of extension cracks (unstable cracking), that is to say the envelope of the damage threshold and the cleavage limit. The long-term resistance threshold therefore coincides with the characteristic threshold defined in paragraph § 1.1.1. Again, the role of these two thresholds should not be confused. The maximum viscoplastic threshold is a mechanic threshold by which the elasticity domain of the viscoplastic mechanism collapses while the characteristic threshold is a transition threshold in the volume behavior for the two mechanisms. With these definitions, an unstable long-term behavior necessarily corresponds to an expanding volume state. The threshold for the initiation of viscoplastic deformations corresponds to the initial elastic limit (damage threshold). The elastic domain of the viscoplastic mechanism therefore changes between the initial elastic limit (which is identical to that of the elastoplastic mechanism) and the long-term resistance threshold. During a creep test, a diverter maintained constant between the initial elastic limit and the maximum viscoplastic threshold corresponds to stable creep (primary creep) and to a contracting volume behavior. A diverter maintained constant between the maximum viscoplastic threshold and the peak threshold corresponds to an unstable long-term behavior and to an expanding volume behavior.

1.3. Anisotropy#

Because of their geological history and their mode of deposition/formation, some geomaterials have one or more preferential orientations; which may have an influence on their instantaneous and/or delayed mechanical behavior. The properties generally affected by this initial anisotropy are: the Young’s modulus, the Poisson’s ratio, the shear modulus, the resistance to simple compression, the amplitude of the delayed deformations,…

Structural (or initial) anisotropy is one of the physical phenomena taken into account by model LKR (see § 2.2 and § 2.5).

1.4. Coupling between the two mechanisms#

As indicated in paragraph 1.2, the maximum resistance achieved during a triaxial compression test depends on the stress rate and therefore on time. However, maximum resistance is a concept solely supported by the plastic mechanism (peak threshold) which is independent of time. To be able to reproduce this kind of phenomenon, it is therefore necessary to couple the two mechanisms in order to introduce, implicitly, the concept of time within the plastic mechanism.

The coupling introduced by [2] takes place at the level of the internal variables for work-hardening of the two mechanisms. When the stress state is above the maximum viscoplastic threshold, the work hardening of the viscoplastic surface influences that of the plastic surface. The reader will refer to [2] for more details on this. The coupling between the two mechanisms will also be mentioned in paragraph 2.6 in which the expressions of the work-hardening variables of the two mechanisms are presented.

1.5. Notes on spherical behavior#

Behavioral model LETK was initially developed to reproduce the behavior of structures during underground excavations. The stress path followed on the gallery wall during an excavation is not spherical. The LETK model is therefore essentially focused on reproducing the deviatoric behavior of geomaterials. Along a purely spherical stress path, the modelled behavior will therefore remain linear elastic*.*